Cascade control is a control system strategy that enhances the performance and stability of control processes by utilizing multiple control loops. It involves a primary (or master) controller and one or more secondary (or slave) controllers, where the primary controller’s output sets the secondary controller’s setpoint. This approach helps manage complex systems where a single control loop may not provide sufficient performance.

Here’s a detailed explanation of cascade control:

Components of Cascade Control

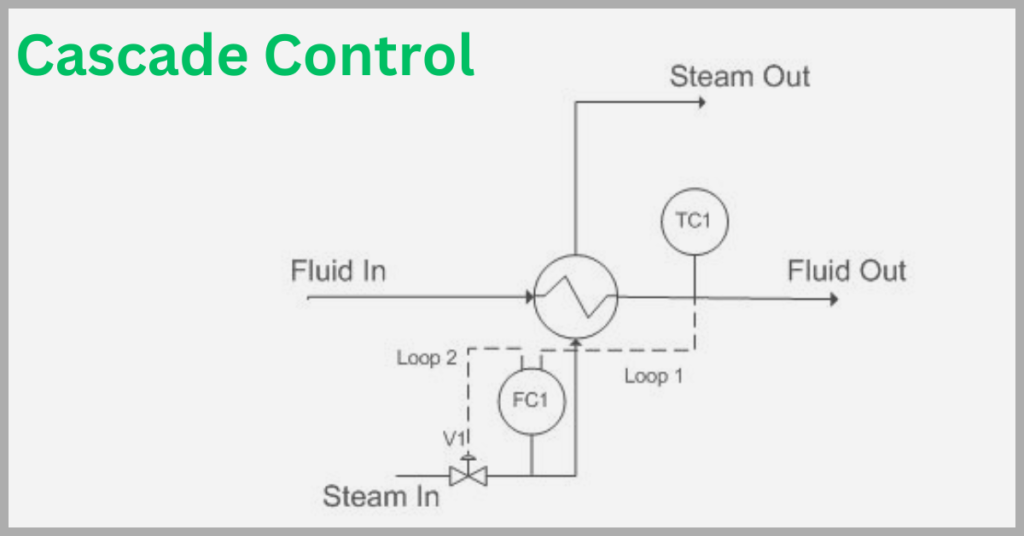

- Primary Controller: This controller manages the main process variable that needs to be controlled. It compares the desired setpoint with the actual process variable and generates an output.

- Secondary Controller: The output of the primary controller serves as the setpoint for the secondary controller. The secondary controller manages a different process variable, typically affecting the main process variable.

How Cascade Control Works

- Primary Loop: The primary controller measures the main process variable (e.g., temperature, pressure) and adjusts its output to maintain the desired setpoint.

- Secondary Loop: The secondary controller receives the output from the primary controller as its setpoint and controls a related process variable (e.g., flow rate, valve position). By stabilizing this secondary process variable, the secondary controller helps maintain the primary process variable more effectively.

Example of Cascade Control

Consider a temperature control system for a chemical reactor:

- Primary Controller: Controls the temperature inside the reactor.

- Secondary Controller: Controls the flow rate of the heating medium (e.g., steam or hot water) to the reactor.

In this setup, the primary controller measures the reactor temperature and adjusts its output to maintain the desired temperature. The secondary controller takes this output and controls the flow rate of the heating medium. By stabilizing the flow rate, the secondary controller helps the primary controller maintain the reactor temperature more precisely.

When to Use Cascade Control?

Cascade control should be used in specific scenarios where its benefits significantly enhance system performance and stability. It is particularly beneficial for processes with fast disturbances, such as a chemical reactor experiencing rapid fluctuations in the flow rate of a cooling or heating medium. Cascade control can quickly correct the secondary variable (flow rate) before it significantly affects the primary variable (temperature).

In processes with slow dynamics, like temperature control in large industrial ovens, the primary process variable (oven temperature) may respond slowly to changes. By controlling a faster secondary process variable (e.g., heat input), cascade control helps achieve more stable and accurate temperature control. This strategy is also advantageous in complex processes with multiple influencing variables, such as paper manufacturing, where both temperature and humidity need to be controlled. Cascade control allows for separate management of these variables, leading to better overall control of the final product quality.

Systems with nonlinearities or interacting variables, such as a distillation column where both temperature and pressure must be controlled, benefit from cascade control by separating their control into different loops. This approach is also ideal for processes requiring enhanced stability and precision, like precision machining, where tool position and speed must be precisely controlled. Cascade control stabilizes the secondary variables that affect the primary variable, providing the required precision.

In processes with measurable intermediate variables, such as controlling steam pressure in a boiler system to maintain boiler temperature, cascade control can be highly effective. If an intermediate variable that influences the primary variable can be measured and controlled, cascade control becomes a powerful tool. This strategy is also valuable in applications requiring a fast response to disturbances, such as servo motor systems where both position and velocity need to be controlled. Cascade control rapidly addresses disturbances affecting the secondary variable (velocity), ensuring the primary variable (position) remains stable.

The benefits of using cascade control in these scenarios include improved disturbance rejection, as cascade control can address disturbances at the secondary level before they propagate to the primary level, enhancing overall system stability. It also enhances control accuracy by managing secondary variables more precisely, which improves the accuracy of the primary control loop. Additionally, cascade control reduces overshoot and settling time, minimizing overshoot and reducing the time it takes for the system to settle at the desired setpoint. Furthermore, it provides better handling of nonlinearities, managing nonlinear behaviors in complex processes more effectively than single-loop control.

In summary, cascade control is particularly advantageous in systems where quick disturbance rejection, enhanced stability, and precise control are crucial. It is most effective in complex processes with measurable intermediate variables and when multiple interacting variables need to be managed simultaneously.

Advantages of Cascade Control

- Improved Performance: By addressing disturbances in the secondary loop before they affect the primary process variable, cascade control can improve the overall system performance.

- Enhanced Stability: Cascade control can reduce the impact of process disturbances and improve the stability of the primary control loop.

- Faster Response: The secondary controller can respond more quickly to changes, allowing the primary controller to maintain the desired setpoint more effectively.

Disadvantages of Cascade Control

- Complexity: Cascade control systems are more complex to design and tune compared to single-loop control systems.

- Increased Cost: Implementing cascade control may require additional sensors, controllers, and wiring, increasing the overall system cost.

Tuning Cascade Control Systems

Tuning a cascade control system involves setting the parameters for both the primary and secondary controllers. Generally, the secondary loop is tuned first to ensure it responds quickly and effectively to disturbances. Once the secondary loop is stable, the primary loop is tuned to achieve the desired control performance.

Applications of Cascade Control

Cascade control is widely used in various industrial applications, including:

- Chemical Processing: For precise control of temperature, pressure, and flow rates.

- Power Plants: To manage boiler temperatures and steam flow rates.

- HVAC Systems: For controlling room temperatures and air quality.

- Manufacturing: To regulate speed and torque in motor control systems.

Overall, cascade control is a powerful strategy for improving control system performance in complex and dynamic processes.

Read Next: