A marshalling cabinet is an electrical control cabinet used in industrial automation systems to terminate, organize, and route field instrument signals between field devices and control systems like DCS or PLC. In simple terms, a marshalling cabinet acts as an interface point where field cables are grouped, cross-wired, and connected to system cables, improving wiring clarity, flexibility, and maintenance efficiency.

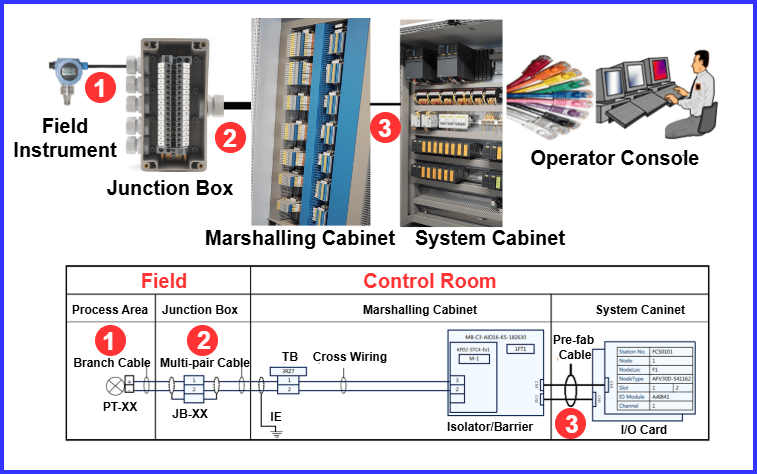

As shown in the images below, conventional cabling involves routing field input and output signals first to a field junction box. From there, the signals are carried to the control room or Instrument Technical Room through a home-run multipair or multicore cable, where they terminate in a marshalling panel. Cross-wiring is then used within the panel to connect each signal to its respective termination assembly.

In simple words, a marshalling cabinet acts as an interface between field junction boxes and the control system. Field cables are terminated inside the marshalling cabinet, where cross-wiring is carried out to arrange signals in line with the assigned I/O modules. This approach allows the use of standardized, prefabricated cables to efficiently connect the marshalling cabinet to the I/O modules, simplifying installation and maintenance.

Cabinet Types

In industrial control systems, cabinets are broadly classified based on their function. The most common cabinet types include:

- System Cabinet

- Marshalling Cabinet

- System cum Marshalling Cabinet

Each type serves a specific role in signal management and control architecture.

System Cabinet

A system cabinet houses control system hardware such as PLCs, DCS controllers, I/O modules, power supplies, and communication cards. It directly processes control logic and data acquisition.

Key features of a system cabinet:

- Contains CPUs and I/O cards

- Handles control logic and processing

- Uses system cables connected from marshalling cabinets

- Located in control rooms or equipment rooms

System cabinets usually do not receive field cables directly, which helps reduce congestion and improve reliability.

Marshalling Cabinet

A marshalling cabinet is specifically designed to terminate field instrument cables and redistribute signals to the system cabinet through multicore or system cables.

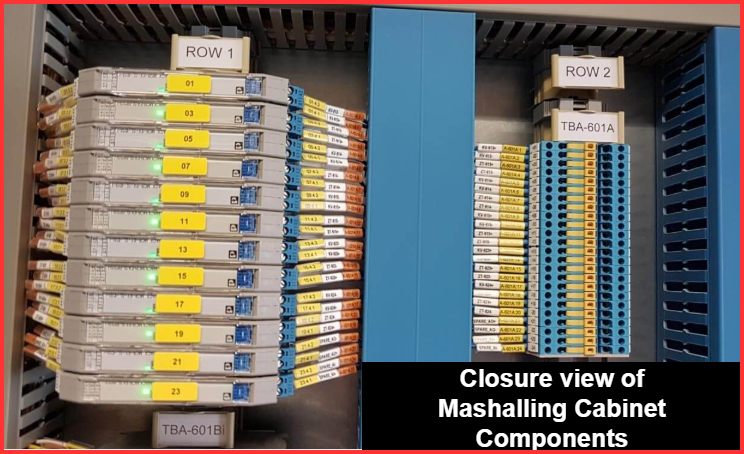

The main elements of a marshalling cabinet include signal isolators or barriers, relays, and terminal blocks used for terminating field home-run cables. It also consists of shield grounding terminals, dedicated terminal boards for cross-wiring, power supply units, and diode ORing modules to ensure reliable and uninterrupted power distribution.

Dedicated marshalling cabinets are typically used in large I/O systems. When marshalling cabinets are provided as separate units, they can be delivered to site at an early stage of the project, allowing field cables to be terminated well in advance of the control system installation.

Once the system cabinets become available, prefabricated cables are installed between the marshalling cabinets and the system cabinets. Using separate cabinets allows staged Factory Acceptance Tests (FAT) and phased delivery, which helps streamline project execution.

However, this approach requires additional site work to install the prefabricated cables. In cases where FAT for both the system and marshalling cabinets is carried out together, the interconnecting cables between the two cabinets are disconnected prior to shipment and reinstalled at site. After delivery to the site, the connections between the marshalling terminals and the I/O terminals need to be re-established.

Main functions of a marshalling cabinet:

- Termination of field cables

- Cross-wiring and signal grouping

- Signal isolation and protection

- Easy loop checking and troubleshooting

By separating field wiring from system hardware, marshalling cabinets make plant expansion and maintenance much simpler.

System cum Marshalling Cabinet

A system cum marshalling cabinet combines both system hardware and marshalling terminals in a single enclosure. This configuration is commonly used in small plants or skid-mounted packages.

The key components of a system cum marshalling cabinet include controllers, I/O modules, power supply units, and diode ORing modules. It also houses isolators or barriers, relays, terminal blocks for terminating field home-run (main) cables, shield grounding terminals, and dedicated terminal boards for cross-wiring.

This combined system cum marshalling cabinet is typically used for small I/O systems. It is commonly applied in packaged control panels where the number of I/O points is limited, making a single cabinet sufficient for both control hardware and signal marshalling.

This type of cabinet is supplied with the controller, I/O modules, terminals, relays, barriers, and other components installed within a single enclosure. In such arrangements, the prefabricated cables are factory-installed, reducing site wiring and installation effort.

Advantages:

- Saves space

- Reduces cabling cost

- Faster installation

Limitations:

- Limited flexibility for future expansion

- Higher risk during maintenance activities

Electronic Marshalling Cabinet

Electronic marshalling cabinets contain specialized I/O modules, adapters, and terminal units that support software-based signal mapping.

This is an advanced concept where signal assignment is carried out through software rather than fixed hardwired terminals. It allows any field signal to be mapped to any available I/O channel without the need for physical rewiring.

With the adoption of universal I/O concepts, field cables are connected directly to the I/O modules themselves. This approach eliminates the need for terminal blocks, cross-wiring, and prefabricated cables typically used in conventional marshalling cabinets. The required I/O type is assigned and configured through software, providing greater flexibility and faster commissioning.

For intrinsically safe applications, the I/O cards are designed with dedicated barrier slots or compatible adapters that allow field cables to be terminated directly on the I/O card.

This latest technology offered by control system suppliers significantly reduces site effort and field wiring, minimizes cabinet footprint, and provides greater flexibility for utilizing spare I/O channels.

Key benefits of electronic marshalling:

- Flexible I/O assignment

- Reduced engineering effort

- Faster project execution

- Ideal for late design changes

Electronic marshalling is widely used in modern DCS systems.

Dedicated Marshalling Cabinets

Dedicated marshalling cabinets are used exclusively for signal termination and marshalling without housing any system electronics.

Why dedicated marshalling cabinets are preferred:

- Clear separation between field and system wiring

- Better heat management

- Safer maintenance

- Easier fault isolation

They are commonly used in large process plants such as refineries, power plants, and chemical industries.

Common Mistakes

Some common mistakes made while designing or installing marshalling cabinets include:

- Poor cable labeling and documentation

- Mixing analog and digital signals without segregation

- Inadequate spare terminals for future expansion

- Improper earthing and shielding practices

- Overcrowding terminals leading to maintenance issues

Avoiding these mistakes ensures reliable system performance and long-term operability.

Advantages of Marshalling Cabinets

- Improved wiring organization

- Simplified maintenance and troubleshooting

- Enhanced system flexibility

- Reduced installation errors

- Better scalability for future expansion

Applications of Marshalling Cabinets

Marshalling cabinets are widely used in:

- Power plants

- Oil and gas industries

- Chemical and petrochemical plants

- Water treatment facilities

- Manufacturing and process automation

Key Design Considerations for Dedicated Marshalling Cabinets

When using dedicated marshalling cabinets, several important points should be carefully addressed during the design stage to ensure flexibility, reliability, and ease of maintenance throughout the project lifecycle.

- Field cable termination:

All conductors from field multipair or multicore cables should be terminated inside the marshalling cabinet. Any change in cable size, such as upgrading from a 16-pair to a 24-pair cable, will increase the number of required terminals and should be accounted for during initial design to avoid space constraints later. - Junction box grouping changes:

Modifications in junction box grouping generally have minimal impact on cross-wiring inside the marshalling cabinet. Importantly, such changes do not affect I/O assignment at the control system level, provided proper marshalling practices are followed. - Redundancy and voting logic:

For parallel equipment and safety-critical configurations such as 2oo3 (two-out-of-three) voting, the associated I/Os should be distributed across different I/O cards. Cross-wiring within the marshalling cabinet can be used effectively to achieve this separation, improving system availability and fault tolerance. - Main cable loading per cabinet:

The number of main (home-run) cables terminated in a single marshalling cabinet should be carefully reviewed. Overcrowding cables can make troubleshooting and maintenance difficult. This consideration applies to all types of marshalling and system cabinets. - Controller-based segregation:

I/O allocation and marshalling cabinet grouping should follow the controller segregation philosophy. Aligning cabinets with specific controllers improves clarity, simplifies maintenance, and reduces the risk of cross-controller wiring errors. This principle is valid for both marshalling and system cabinets. - Future expansion and spares:

Adequate spare terminals, wiring ducts, and cabinet space should be provided to accommodate future I/O additions or design changes without major rework. - Cabinet construction and compliance:

Cabinet-related parameters such as dimensions, color, access type (front/rear), spare space, spare components, internal wiring and duct color, duct size, cable entry (top or bottom), smoke detection provisions, ingress protection (IP) class, EMC compliance, and earthing arrangements must be finalized based on project specifications, site conditions, and applicable standards. - Maintainability and documentation:

Proper tagging, labeling, and documentation should be planned during the design stage to ensure easy identification of cables and terminals during installation, commissioning, and long-term operation.

Addressing these points early in the design phase helps optimize cabinet layout, reduces site rework, and ensures smooth project execution when using dedicated marshalling cabinets.

Conclusion

A marshalling cabinet plays a vital role in industrial automation by providing a structured and flexible interface between field instruments and control systems. Whether using conventional wiring or advanced electronic marshalling, properly designed marshalling cabinets improve reliability, simplify maintenance, and support future system expansion. Choosing the right type of marshalling cabinet ensures efficient signal management and long-term operational success.

Read Next: