Level transmitters are crucial instruments in industrial processes, measuring liquid levels in tanks, vessels, and pipelines. Over time, these devices may lose accuracy due to environmental conditions, mechanical wear, or electronic drift. This is where Level Transmitter Calibration becomes essential. Regular calibration ensures reliable measurements, process efficiency, and safety.

What is Level Transmitter Calibration?

Level Transmitter Calibration is the process of verifying and adjusting a level transmitter so that its output accurately reflects the true level of the measured liquid. Calibration involves comparing the transmitter’s output with a known reference standard and making necessary adjustments to correct any deviations.

Proper calibration guarantees:

- Accurate level measurement

- Optimal process control

- Reduced wastage and safety risks

- Compliance with industrial standards

Tools and Equipment Required for Calibration

To perform a Level Transmitter Calibration, you need the following:

- Calibration Bench or Test Rig – Provides a controlled environment for safe testing.

- Reference Level Standard – Usually a precise liquid column, master transmitter, or calibrated device.

- Multimeter or Signal Analyzer – To measure the transmitter’s electrical output (4–20 mA or other signal types).

- Calibration Software (if digital) – For HART or smart transmitters.

- Tools for Adjustment – Screwdrivers, wrenches, or transmitter-specific tools.

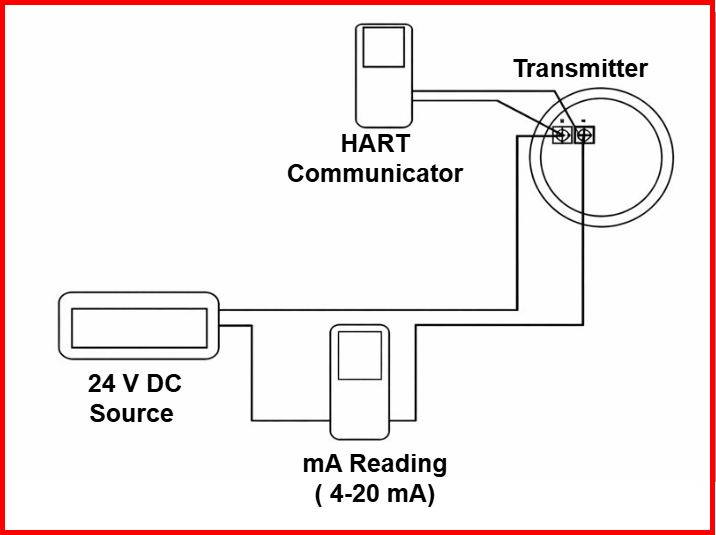

Calibration Setup Diagram :

Step-by-Step Level Transmitter Calibration Procedure

1. Isolate the Transmitter

- Turn off process flow to the tank or vessel.

- Close isolation valves to safely remove or access the transmitter.

- Ensure the transmitter is depressurized if needed.

2. Connect to Calibration Equipment

- Connect the transmitter to the calibration bench or test rig.

- For smart transmitters, connect using HART or device-specific communication tools.

3. Apply Known Reference Levels

- Simulate liquid levels using a reference standard or test fluid.

- Start with 0% level (empty) and gradually increase to 100% (full) in steps.

4. Record Output Signals

- At each reference level, record the transmitter output (usually 4–20 mA).

- Compare the readings with the expected values.

5. Adjust the Transmitter

- If deviations are detected, adjust the zero and span settings.

- Zero adjustment: Corrects the transmitter reading at the lowest level.

- Span adjustment: Corrects the transmitter reading at the highest level.

- Some digital transmitters allow software-based adjustment, eliminating the need for physical tools.

6. Verify Calibration

- Repeat the measurement process to confirm that the transmitter accurately reflects the reference levels.

- Ensure the output falls within the manufacturer’s specified tolerance.

7. Reinstall the Transmitter

- Carefully return the transmitter to its operating position.

- Open the isolation valves and resume normal process flow.

Best Practices for Level Transmitter Calibration

- Perform calibration at regular intervals as recommended by the manufacturer.

- Document every calibration procedure for compliance and future reference.

- Use certified reference standards for accurate calibration.

- Avoid calibration during unstable process conditions to reduce errors.

- For hazardous or pressurized systems, follow proper safety protocols.

Common Types of Level Transmitters and Their Calibration Notes

- Differential Pressure Level Transmitters – Calibrate using a pressure test rig.

- Ultrasonic Level Transmitters – Calibration requires checking distance and echo response.

- Radar Level Transmitters – Use process simulation or calibration blocks.

- Float-based Level Transmitters – Physical verification of float travel is needed.

Conclusion

Level Transmitter Calibration is a vital maintenance activity that ensures accurate level measurement, process efficiency, and safety. Following a systematic procedure, using proper calibration tools, and adhering to manufacturer guidelines will prolong the transmitter’s life and prevent costly process errors. Regular calibration is not just a best practice—it is a necessity for reliable industrial operations.

Read Next: