A coriolis mass flow meter is a highly accurate flow-measuring instrument used to directly measure the mass flow rate of liquids and gases. Unlike conventional flowmeters that depend on pressure or velocity, a coriolis mass flowmeter works on the Coriolis effect, making it independent of fluid properties such as density, viscosity, and temperature.

It is regarded as a true mass flow measuring device because it determines the mass flow rate directly. In contrast, most other flowmeter technologies primarily measure volumetric flow and then calculate mass flow indirectly using density compensation.

Because mass remains constant, variations in fluid properties do not require any correction or adjustment. As a result, a Coriolis meter delivers a linear and consistent output across a wide range of operating conditions.

Due to its precision and reliability, it is widely used in industries like oil and gas, chemical processing, food and beverage, and pharmaceuticals.

Components of Coriolis Mass Flow Meter

A Coriolis mass flow meter consists of several key components that work together to ensure accurate measurement.

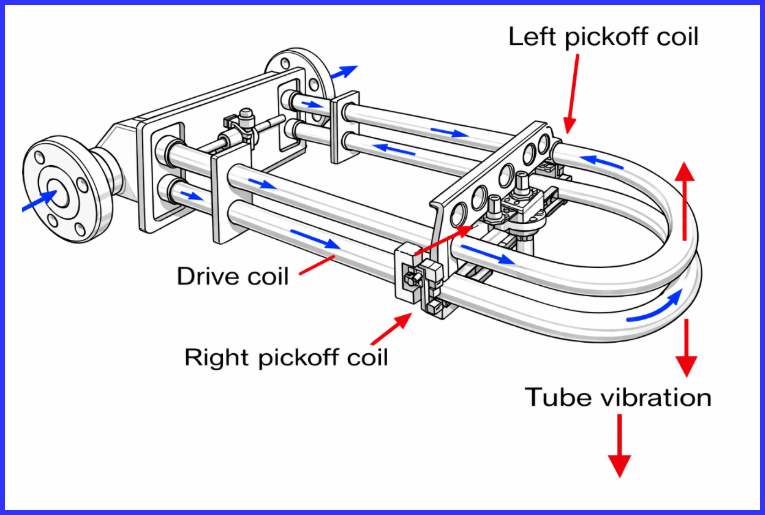

- Flow Tubes

These are specially designed tubes through which the fluid flows. They vibrate at a fixed frequency during operation. - Drive Coil (Exciter)

The drive coil induces controlled vibrations in the flow tubes. - Sensors (Pick-off Sensors)

Sensors detect the phase shift or time difference caused by the Coriolis force when fluid flows through the vibrating tubes. - Temperature Sensor

Measures fluid temperature to compensate for thermal effects and improve accuracy. - Signal Processor / Transmitter

Converts sensor signals into usable outputs such as mass flow rate, density, and temperature.

Working Principle of Coriolis Mass Flow Meter

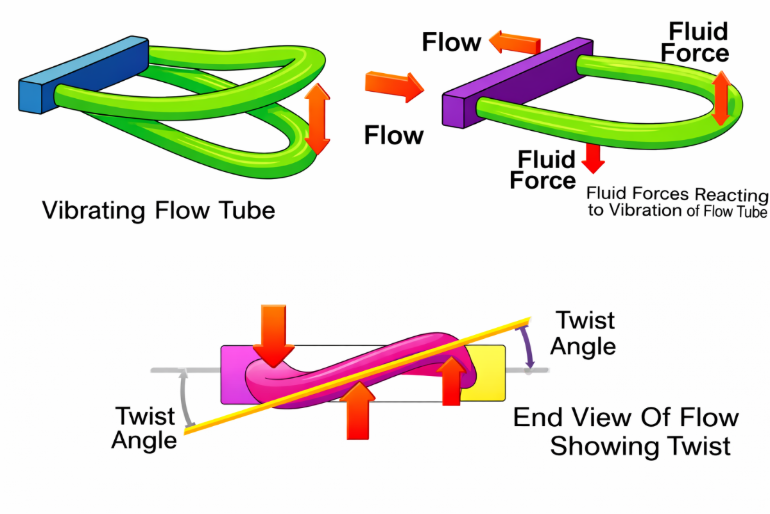

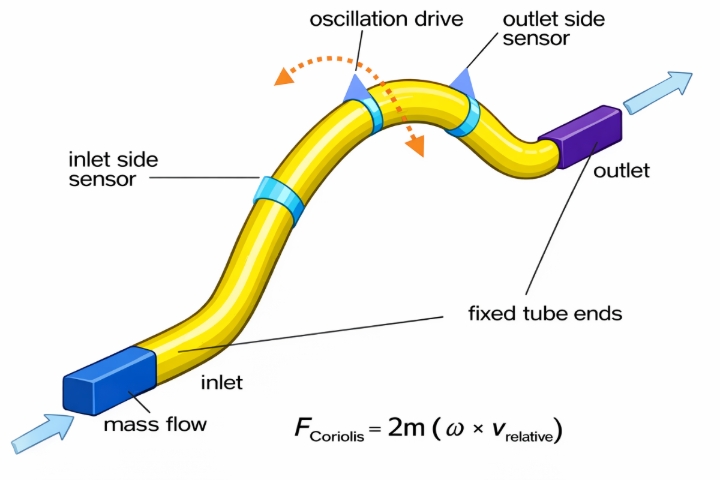

In a Coriolis mass flow meter, the process fluid is directed through a U-shaped tube. An external excitation force is applied to the tube, causing it to vibrate at a fixed frequency. When fluid flows through this vibrating tube, Coriolis acceleration acts on the fluid in opposite directions on either side of the excitation force, resulting in a rotational twist of the tube.

During the first half of the vibration cycle, the tube moves upward. At this moment, the fluid entering the meter resists the upward motion and pushes downward on the tube. Simultaneously, the fluid leaving the meter resists a reduction in its vertical velocity and pushes upward on the tube. This unequal force distribution causes the tube to twist.

In the second half of the vibration cycle, when the tube moves downward, the twisting occurs in the opposite direction. This alternating twist creates a measurable phase difference (time lag) between the inlet and outlet sides of the tube.

The magnitude of this phase difference is directly proportional to the mass flow rate of the fluid passing through the tube.

Coriolis Effect and Direct Mass Flow Measurement

One major advantage of Coriolis flow meters is that they measure mass flow directly, eliminating the need for compensation due to changes in temperature, viscosity, or pressure. This makes them highly reliable for precise flow measurement.

Modern Coriolis meters are also available in single straight-tube designs, which are suitable for handling dirty or abrasive fluids that could clog traditional U-shaped tubes.

For proper operation, a minimum gas density of approximately 4.5 kg/m³ is typically required, although this value may vary depending on the manufacturer.

Coriolis Force Equation

Theoretically, the Coriolis force is expressed as:

Fc = 2 × m × ω × V

Where:

- m = mass (kg)

- ω = angular velocity (rad/s)

- V = velocity (m/s)

U-shaped and Ω-shaped Coriolis meters experience an increase in pressure drop as flow rate increases, resulting in permanent pressure loss. If the liquid is close to its boiling point, this pressure drop may cause cavitation, where vapor bubbles form as pressure falls below the vapor pressure. These bubbles collapse when pressure recovers, potentially damaging the meter and affecting accuracy.

Cavitation leads to meter malfunction and must be avoided at all times.

To generate stronger Coriolis forces, the tube cross-section is smaller than the pipeline cross-section, increasing fluid velocity. This design principle also applies to straight-tube Coriolis meters and contributes further to pressure drop.

Coriolis mass flow meters can accurately measure mass flow rate and true density regardless of fluid composition, provided the flow remains single-phase and homogeneous. Due to this high accuracy, they are widely used in custody transfer, reactor feed ratio control, and applications involving large variations in fluid composition.

A known limitation is the need for zero adjustment under operating conditions. Improper or stress-induced installation can disturb the zero setting, affecting measurement accuracy.

The importance of zero adjustment is reflected in the uncertainty equation:

± [(Zero Stability / Flow Rate) × 100]% ± x%

Where x typically ranges between 0.1% and 0.3%, depending on meter design.

Main Features

intact while improving clarity and readability:

- Coriolis meters are suitable for a wide range of applications, from high-viscosity fluids such as adhesives and coatings to cryogenic services like liquid nitrogen.

- Curved-tube Coriolis meters offer excellent rangeability, typically in the range of 100:1 to 200:1, allowing accurate measurement over a wide flow span.

- Straight-tube Coriolis meters have a comparatively lower rangeability, usually around 30:1 to 50:1, and their measurement accuracy is generally lower than curved-tube designs.

- Coriolis meters do not require compensation for changes in temperature or pressure, as they directly measure mass flow.

- The mass flow measurement remains unaffected by variations in fluid viscosity or density.

- These meters are especially effective for fluids whose viscosity varies with flow velocity, even when temperature and pressure remain constant.

- Coriolis flow meters are often referred to as universal meters because they can measure almost all types of fluids, including liquids, slurries, and gases.

- They are capable of measuring Newtonian fluids, non-Newtonian fluids, and moderately dense gases with high accuracy.

- In addition to mass flow, Coriolis meters can also be used for direct liquid density measurement.

- There are no Reynolds number limitations associated with Coriolis flow meters.

- Measurement accuracy is not influenced by distorted or uneven velocity profiles.

Advantages of Coriolis Meters

Here are the advantages of a Coriolis mass flow meter,

- Capable of measuring a wide variety of fluids that are difficult to handle with conventional flowmeters.

- Operates independently of the Reynolds number, allowing accurate measurement of very high-viscosity fluids.

- Suitable for measuring:

- Newtonian fluids

- All types of non-Newtonian fluids

- Slurries

- Certain designs can also measure compressed gases and cryogenic liquids.

- Provides direct mass flow measurement, eliminating the need for additional compensation devices.

- Mass flow measurement is independent of density variations, unlike volumetric flow measurement.

- Offers excellent accuracy, typically around ±0.2%, with consistent linear performance across the full flow range.

- High rangeability (generally 20:1 or higher), enabling reliable measurement at very low flow rates.

- A single instrument can measure multiple parameters, including:

- Mass flow rate

- Volumetric flow rate

- Fluid density

- Fluid temperature

- Performance is unaffected by turbulence, flow profile distortion, or pulsating flow.

- Does not require upstream or downstream straight pipe lengths, simplifying installation.

- Contains no internal obstructions or moving parts, preventing wear and blockage.

- Slurries and suspended solids do not damage the meter, and entrained gas pockets do not cause mechanical failure.

- Low mechanical complexity results in minimal maintenance requirements.

- Supports bidirectional flow measurement, accurately detecting both forward and reverse flow.

- In reverse flow conditions, the phase shift reverses direction, ensuring correct flow indication.

- Available in sanitary designs for hygienic applications and suitable for shear-sensitive fluids.

- Manufactured using materials compatible with corrosive fluids, enabling use in harsh process environments.

Disadvantages of Coriolis Meters

- Coriolis flow meters are not well suited for very large pipe diameters. The largest commercially available units typically support pipe sizes up to 6 inches, with a maximum mass flow capacity of approximately 25,000 lb/min (11,340 kg/min). For higher flow rates, multiple meters must be installed in parallel, increasing system complexity.

- Certain Coriolis meter designs require very high fluid velocities to produce a measurable phase shift between sensor signals. This requirement can result in a significant pressure drop across the meter.

- The initial cost of Coriolis flow meters is relatively high compared to many traditional flow measurement technologies. However, when compared to the combined cost of a volumetric flow meter and a separate densitometer, the overall investment may be comparable.

- Measuring low-pressure gas flow is challenging for Coriolis meters. Applications operating below approximately 150 psig often fall near the lower performance limit of available designs.

- Low-pressure gases have low density and low mass flow rates, making it difficult to generate sufficient Coriolis force for accurate detection.

- To compensate for low gas density, very high gas velocities are required, which can lead to excessive pressure loss across the meter and limit practical application.

Conclusion

A coriolis mass flowmeter is one of the most advanced and reliable flow-measurement devices available today. Its ability to measure mass flow directly with high accuracy makes it the preferred choice for critical industrial applications. Although the initial cost is higher, the long-term benefits in accuracy, reliability, and reduced maintenance justify the investment in a coriolis mass flowmeter.

Read Next:

- Orifice Beta Ratio: Definition, Importance, and Why It Is Between 0.3 to 0.7

- Basics of Orifice Plates

- What is a Bridle? Bridle Piping, Level Measurement & Applications

- Orifice Plate Tapping – Types of Orifice Plate Taps Explained

- Flow Switch Symbols

- Relationship Between Cv and Kv- Cv to Kv Conversion