Bellows in instrumentation play a vital role in pressure and mechanical measurement systems used in industrial processes. These devices are widely valued for their accuracy, flexibility, and ability to measure low and medium pressures effectively. In many industries, bellows for pressure measurement are preferred because they can convert pressure changes into precise mechanical motion. Due to their simple construction and reliable performance, bellows instruments are commonly used in pressure gauges, control systems, and process automation.

What Are Bellows in Instrumentation?

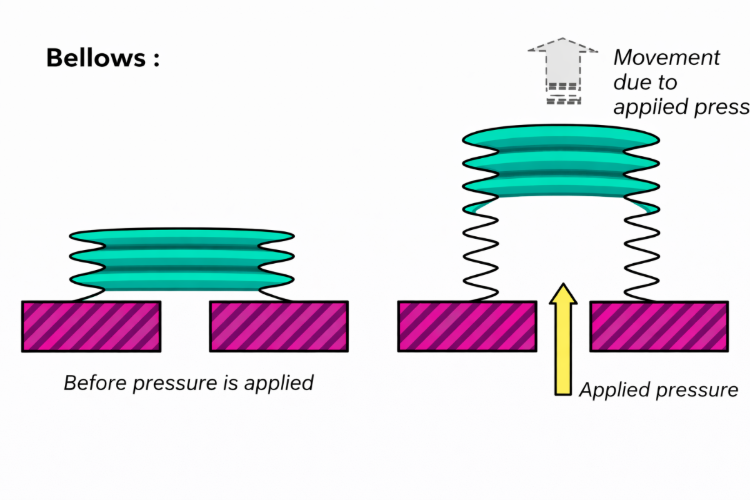

Bellows are mechanical elements made from thin-walled metallic or non-metallic material, shaped into a series of convolutions. These convolutions allow the bellows to expand or contract when pressure is applied.

In instrumentation, bellows act as primary sensing elements. When pressure enters the bellows, it causes axial movement. This movement is proportional to the applied pressure and is used to indicate, record, or control process variables.

Construction of Bellows

The basic construction of bellows includes:

- Thin-walled cylindrical body

- Multiple corrugations or folds

- Fixed end and movable end

- Pressure inlet connection

Materials commonly used include bronze, stainless steel, brass, phosphor bronze, and beryllium copper. The choice of material depends on pressure range, temperature, and corrosion resistance.

Working Principle of Bellows for Pressure Measurement

The working principle of bellows for pressure measurement is simple and effective.

- Pressure is applied inside the bellows

- The bellows expands or contracts axially

- The displacement is proportional to pressure

- Mechanical motion is transmitted to a pointer or control mechanism

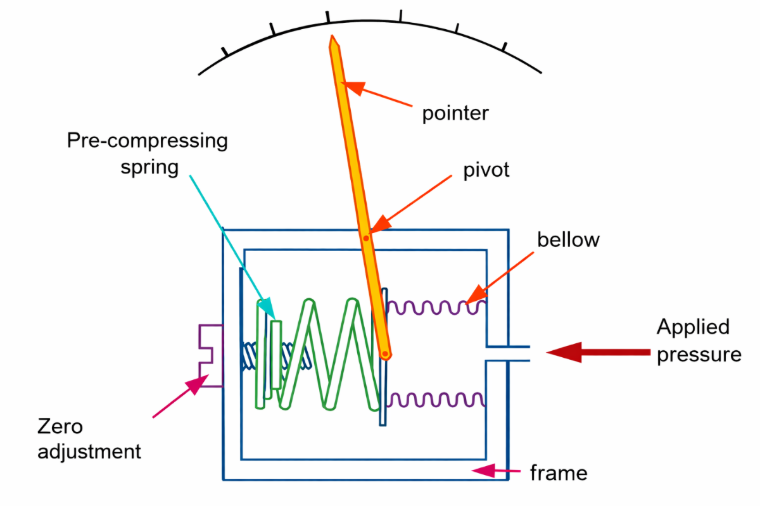

This displacement can be amplified using levers or linkages and converted into readable output in a bellows pressure gauge.

Bellows Type Pressure Gauge

A bellows type pressure gauge uses bellows as the sensing element instead of a Bourdon tube. These gauges are ideal for low-pressure applications.

Key Features:

- High sensitivity

- Accurate low-pressure measurement

- Compact design

- Suitable for vacuum and differential pressure

Because of these advantages, bellows gauges are widely used in laboratories and process industries.

Bellows Gauge and Bellow Gauge Explained

The terms bellows gauge and bellow gauge are often used interchangeably in industry. Both refer to pressure-measuring devices that utilize bellows as the sensing element.

Similarly, bellow gauges and bellow type pressure gauge describe instruments designed for measuring small pressure variations with high precision.

Types of Bellows Instruments

Different bellow instruments are used based on application requirements:

1. Pressure Measuring Bellows

Used in bellows pressure gauges for low pressure and vacuum measurement.

2. Differential Pressure Bellows

Measures the difference between two pressure points.

3. Temperature-Compensated Bellows

Used where temperature variation affects measurement accuracy.

4. Control Bellows

Common in pneumatic control systems and regulators.

Advantages of Bellows in Instrumentation

- High sensitivity for low pressure

- Simple mechanical design

- Good repeatability

- Can measure vacuum and differential pressure

- Suitable for harsh industrial environments

Limitations of Bellows Instruments

- Limited pressure range

- Sensitive to overpressure

- Metal fatigue over long-term use

- Requires protection against vibration

Applications of Bellows Pressure Gauge

Bellows instruments are used in many industries, including:

- Oil and gas industries

- Power plants

- HVAC systems

- Chemical processing plants

- Pneumatic control systems

- Vacuum measurement applications

Comparison with Other Pressure Measuring Devices

| Device Type | Pressure Range | Sensitivity | Typical Use |

| Bellows Gauge | Low to medium | High | Low pressure and vacuum measurement |

| Bourdon Tube | Medium to high | Medium | General industrial pressure measurement |

| Diaphragm Gauge | Low | High | Corrosive and low-pressure fluids |

Conclusion

Bellows in instrumentation remain an essential component for accurate pressure measurement, especially in low-pressure and vacuum applications. Their simple construction, high sensitivity, and reliability make bellows for pressure measurement a preferred choice in many industries. Whether used in a bellows pressure gauge, bellow type pressure gauge, or advanced control systems, bellows instruments continue to support safe and efficient industrial operations.

Read Next: