Instrumentation Maintenance is a critical aspect of ensuring that industrial processes run smoothly, efficiently, and safely. Proper maintenance of instruments, along with timely calibration, guarantees the accuracy, reliability, and longevity of equipment used in industrial operations. Companies that focus on regular instrumentation maintenance can minimize downtime, reduce errors, and enhance overall productivity.

Instrument Maintenance

Instrument maintenance refers to the systematic inspection, servicing, and repair of industrial instruments. It ensures that devices like pressure gauges, flow meters, temperature sensors, and control systems function accurately. Effective maintenance involves a combination of preventive, concurrent, and reliability-centered approaches to safeguard instrument performance.

Preventive Maintenance

Effective instrumentation maintenance is essential for ensuring the accuracy, safety, and reliability of industrial processes. Industrial instrumentation systems must be integrated into the facility’s overall preventive maintenance (PM) program to maintain consistent performance and minimize unexpected downtime.

Preventive maintenance is scheduled at regular intervals to prevent equipment failure and maintain operational efficiency. Key activities include:

- Routine inspections of instruments and maintenance instruments

- Cleaning and lubrication of components

- Checking for wear and tear

- Calibration to ensure accuracy

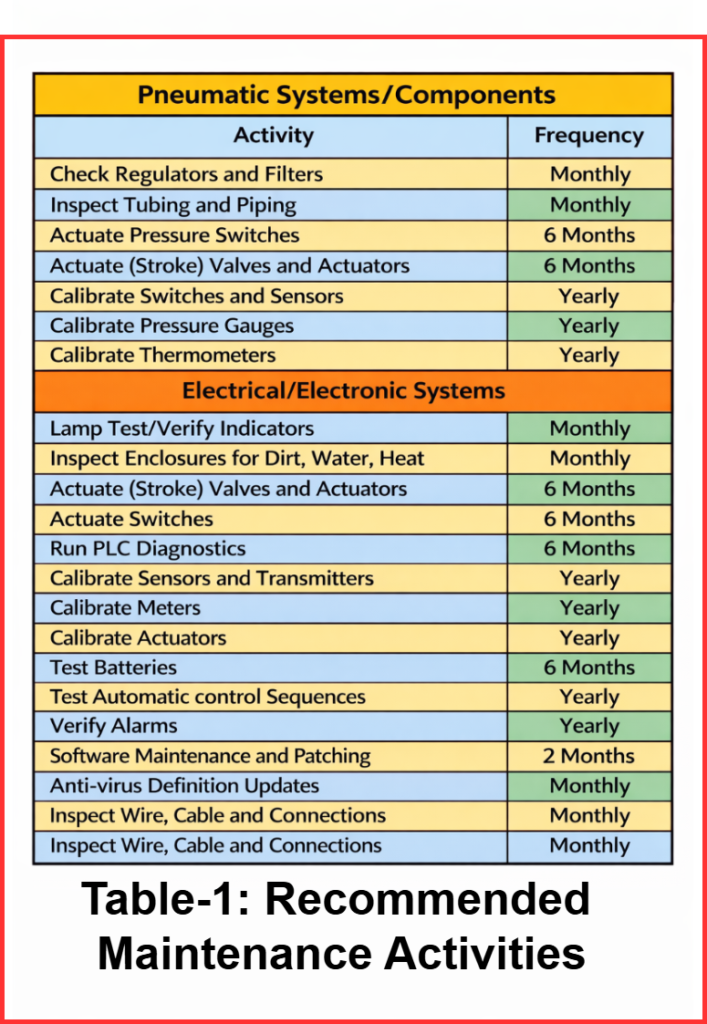

These preventive measures not only extend the life of industrial instruments but also reduce unplanned disruptions. Table 1 provides a list of recommended maintenance tasks and their suggested frequencies for industrial instrumentation devices and components. Preventive maintenance schedules should be coordinated with the mechanical and electrical systems they support to minimize total planned downtime.

Note: Calibration intervals may vary depending on company policies, operational standards, or manufacturer recommendations.

Many components of industrial instrumentation, such as relays, remain inactive under normal operating conditions. To ensure reliable performance during off-normal situations, control systems must be periodically tested under actual or simulated contingency scenarios. For example, SCADA systems managing standby generator plants should be verified by simulating utility power interruptions as far upstream as possible from the regular service point.

Software Maintenance

Maintaining instrumentation software is equally important for consistent operation. Best practices include:

- Updating software to the latest versions provided by the supplier or OEM

- Testing software on engineering or operational workstations to ensure proper functionality

- Regularly updating antivirus software, either online or offline

SCADA computers should remain disconnected from the Internet during normal operations to maintain system security and operational integrity.

Electrical Power Systems

Reliable instrumentation maintenance also depends on properly maintained electrical power systems. AC and DC power supplies that support SCADA and other instrumentation devices should be maintained according to established standards to ensure uninterrupted operation.

In conclusion, integrating preventive maintenance into instrumentation maintenance programs is vital for industrial reliability. Scheduled inspections, cleaning, calibration, contingency testing, software updates, and power system upkeep collectively enhance the accuracy, longevity, and safety of industrial instrument works. Companies that follow these practices can reduce downtime, improve productivity, and ensure their maintenance instruments perform optimally throughout their operational life.

Concurrent Maintenance

Concurrent maintenance refers to the process of testing, troubleshooting, repairing, or replacing a component or subsystem while one or more redundant components or subsystems continue to handle the operational load. This approach ensures that industrial processes remain uninterrupted, which is vital for achieving high reliability and availability targets in modern facilities.

The capability to perform concurrent maintenance is a key design consideration in SCADA systems and industrial control networks. Systems must be architected to allow certain components to be serviced or tested without affecting the overall operation. This is especially important for critical instrumentation and control equipment, where downtime can result in production loss or safety hazards.

For SCADA components linked to equipment with redundancy—but which are not themselves redundant—their maintenance should ideally be coordinated with the maintenance schedule of the associated equipment. This alignment minimizes disruption and ensures seamless operation during service activities.

When SCADA components and controllers are redundant, they must be designed to allow one unit to be taken offline for repair, replacement, or testing while the redundant unit continues to operate normally. This ensures continuous system functionality, maintains operational safety, and supports long-term reliability goals for industrial instrumentation.

Proper planning of concurrent maintenance not only improves system availability but also enhances the efficiency of maintenance instruments and reduces the risk of unexpected failures. Industrial facilities that implement robust concurrent maintenance practices can achieve higher uptime, lower operational costs, and optimized performance of industrial instrument works.

Reliability-Centered Maintenance

Reliability-Centered Maintenance (RCM) is a strategic approach for designing and implementing an effective maintenance program based on the reliability and criticality of individual components, subsystems, and the overall system, while considering safety and cost-effectiveness. Unlike traditional preventive maintenance methods, RCM focuses on optimizing maintenance activities to maximize equipment uptime, minimize operational risks, and ensure safe and economical operations.

RCM specifically emphasizes maintaining critical instruments based on their importance to the industrial process. By prioritizing maintenance tasks that prevent significant failures, RCM ensures operational safety, reliability, and efficiency. The key elements of an RCM strategy include:

- Risk assessment of instruments to identify the most critical components

- Failure mode analysis to understand potential breakdowns and their consequences

- Optimized maintenance schedules to ensure timely interventions without unnecessary downtime

This structured methodology has transformed preventive maintenance from a trial-and-error practice to a data-driven, intelligent planning process. Instead of relying solely on fixed schedules, RCM determines maintenance intervals based on reliability analysis, ensuring that maintenance instruments and industrial instrument works are maintained efficiently.

Modern SCADA systems play a significant role in supporting RCM. The trending, data logging, and historical storage features of SCADA provide valuable operational data that can be used for automated performance monitoring. This data helps detect anomalies early, supports predictive maintenance, and informs maintenance decisions for both mechanical and electrical systems.

Implementing RCM in industrial facilities enhances the longevity and reliability of instrumentation, reduces unplanned downtime, and improves overall productivity. By integrating SCADA data with RCM principles, companies can achieve a smarter, proactive instrumentation maintenance strategy that balances performance, safety, and cost.

Operations & Maintenance Documentation

A design or engineering agency should conduct a thorough Operations & Maintenance (O&M) analysis to identify the specific data necessary to support effective maintenance of the control system. This analysis should be carried out in close coordination with the OEM to define critical maintenance parameters and requirements.

Proper O&M documentation is essential for efficient instrumentation maintenance and helps ensure compliance, streamline troubleshooting, and facilitate planning of future maintenance activities. Key O&M data typically includes:

- System documentation – comprehensive manuals, schematics, and operational guidelines

- Maintenance schedules and history – records of past inspections, servicing, and preventive maintenance activities

- Calibration certificates – proof of instrument calibration to maintain accuracy and reliability

- Instrument specifications and manuals – detailed information for proper operation and servicing

- Service reports – records of repairs, troubleshooting, and replacement activities

- Minimum spare parts list – essential components required for quick replacements

- Recommended spare parts list – additional components to ensure optimal system reliability

- Recommended onsite test equipment – tools and instruments necessary for accurate testing and troubleshooting

- Recommended O&M training – structured training programs for maintenance personnel

- Recommended O&M activities to be performed under contract – tasks requiring specialized expertise or OEM support

Maintaining accurate and up-to-date documentation ensures that industrial instrument works are managed efficiently, reduces downtime, and provides maintenance teams with the guidance, tools, and historical data necessary for reliable operation.

Spare Parts Stocking

Maintaining an adequate on-site inventory of spare parts is vital for achieving high availability and reliability of industrial control and instrumentation systems. Reliability analyses targeting “six nines” (99.9999%) uptime often assume repair times based on “replace with spare,” which are considerably shorter than those for repairing failed components. If spare parts are insufficient, actual system availability can fall well below these calculated reliability targets.

Key considerations for effective spare parts management include:

- Stocking frequently used parts to handle routine failures quickly

- Identifying critical spares for essential instruments to minimize downtime

- Timely procurement to avoid delays in replacing failed components

- Manufacturer’s recommended spare parts list for each system

- One of each line-replaceable board or module

- Six of each power and control fuse used in the system

- Tools required for terminating coaxial or fiber optic cables

Additionally, system specifications should ensure the following items are provided with each installation:

- Laptop computer preloaded with the software required to access controllers

- Licenses for all installed software

- Permission to modify program code for maintenance purposes

- Spare cables for connecting the laptop to controllers

By maintaining a well-stocked inventory of both standard and critical spare parts, maintenance teams can restore industrial instrument works to operational condition quickly, reducing downtime and enhancing the efficiency of instrumentation maintenance programs.

Technical Support

The design agency should clearly define the functional areas of the operating system and equipment where a technical representative from the manufacturer will be provided for training, testing, checkout, validation, or pre-operational exercises. Effective ongoing Operations & Maintenance (O&M) of control system software often requires specialized technical support from the system vendor or from agency technical personnel who may not be physically present at the industrial facility.

Modern commercial SCADA and PLC software generally include provisions for remote access via modems or secure network connections, enabling vendors or central engineering groups to perform troubleshooting, updates, and system validation without onsite presence. While remote access enhances support efficiency, it also introduces potential cybersecurity risks. Unauthorized access to SCADA systems or PLC controllers can compromise control programs, data integrity, and overall system safety.

To mitigate these risks, remote access must be carefully managed:

- Monitoring during use – Remote sessions should be actively monitored by authorized personnel

- Physical disconnection when idle – Systems should be disconnected from remote access channels when not in use

- Password protection policies – All SCADA and PLC systems must comply with industry standards for password management. Default passwords provided by suppliers must be changed before commissioning

- User access control – Assign user roles and permissions to restrict access to critical functions

- Audit trails and logging – Record remote access activities to track changes, modifications, and system interactions

- Firewall and network security – Implement layered network security measures to protect controllers and HMI processors from unauthorized access

Additionally, training programs should ensure that maintenance personnel understand proper procedures for software updates, patch management, and remote troubleshooting. Proper technical support and software maintenance not only maintain the integrity of the instrumentation system but also support continuous operational reliability, minimize downtime, and enhance overall instrumentation maintenance efficiency.

Conclusion

In conclusion, instrumentation maintenance is a cornerstone of efficient industrial operations. Through preventive, concurrent, and reliability-centered maintenance, along with proper calibration, documentation, spare parts management, and technical support, industries can ensure accurate and reliable performance of their instruments. Investing in a systematic instrument maintenance program reduces downtime, improves safety, and boosts productivity.

Read Next: