A Bubbler Level Sensor consists of a tube with its opening submerged below the liquid level. A steady flow of air is continuously passed through this tube and released at the submerged end. The pressure generated inside the tube corresponds directly to the depth and density of the liquid above the outlet.

Since bubbler sensors have no moving components, they require minimal maintenance compared to most other level measurement techniques. The only part that comes into contact with the liquid is the bubble tube, which is selected during the design phase to ensure chemical compatibility with the measured substance.

Bubbler Level Sensor Working

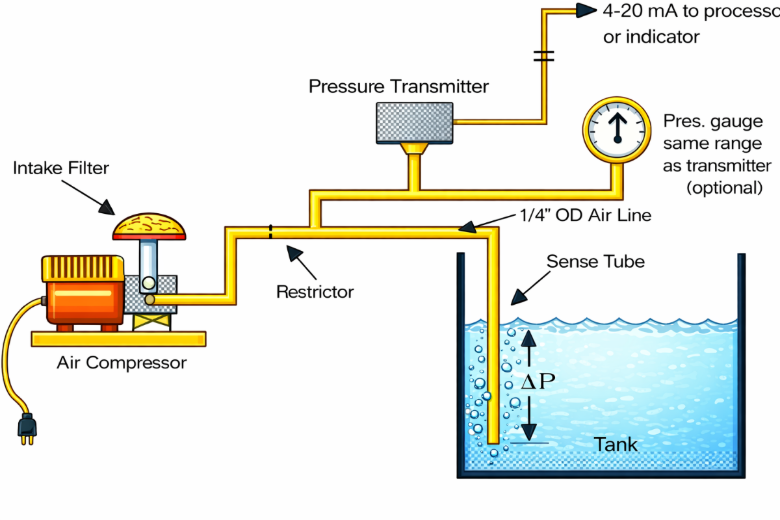

A Bubbler Level Sensor measures the liquid level by using a submerged tube and a continuous air or gas flow. The tube’s opening is positioned below the surface of the liquid. When a steady airflow is introduced into the tube, bubbles escape from the submerged end. A basic diagram illustrating the operation of an air bubbler level measurement system is shown below.

The pressure inside the tube increases in proportion to the depth of the liquid above the opening. This pressure is measured using a pressure transmitter, which converts it into an electrical signal corresponding to the liquid level. Because the system has no moving parts in contact with the liquid, it is highly reliable and requires minimal maintenance.

Bubbler systems can use air or inert gases like nitrogen, especially in flammable liquid applications, where the gas also forms a protective blanket above the liquid surface to prevent vapor escape. Additionally, the system can be configured with a high-pressure bypass to clear debris or solids, making it inherently self-cleaning and suitable for industrial tanks with sediments or viscous liquids.

Applications of Bubbler Level sensor

Safety and Hazardous Area Applications

The Bubbler Level Sensor is particularly well-suited for hazardous environments because it eliminates the risk of electrical sparks, as no electrical components come into direct contact with the liquid. This makes it an ideal choice for measuring flammable, corrosive, or volatile liquids in chemical plants, refineries, and fuel storage facilities.

The air supply pump or compressor, which maintains a consistent airflow through the sensor, can be installed remotely in a safe, non-hazardous area, further minimizing potential exposure to dangerous substances.

Additionally, because the system relies on pneumatic pressure rather than electronics, it reduces the risk of ignition, ensuring a safer operation in classified zones.

Suitability for Open Tanks

Air bubbler systems are an excellent solution for open tanks operating at atmospheric pressure. They can be designed with a high-pressure air bypass that periodically clears any debris or solids that might block the bubble tube, making the system essentially self-cleaning.

This feature ensures reliable and continuous liquid level measurement even in tanks containing slurries, sediments, or viscous liquids.

Because of their simplicity and robustness, air bubblers are often preferred in applications where ultrasonic, float, or microwave level measurement methods have proven unreliable or inconsistent, particularly in harsh industrial environments.

Additionally, these systems are easy to maintain and can be adapted for large storage tanks, making them versatile for a wide range of industrial processes.

Industry Usage and Limitations

Air bubbler systems have historically been used in the fuel storage industry, though their adoption has been limited and is gradually declining in favor of more advanced servo gauges and radar-based level measurement systems.

This shift is driven partly by the specialized maintenance requirements of air bubbler setups, which involve valves, compressors, and other mechanical components. Another factor is the measurement accuracy, typically around ±10 mm, which is less precise compared to modern servo or radar gauges.

Despite being called “air bubblers,” these systems are not restricted to using air. In applications involving flammable liquids, such as gasoline or other volatile substances, it is common to use nitrogen instead.

Nitrogen is preferred because, after passing through the liquid, it forms a protective gas blanket above the surface. This nitrogen layer helps prevent the escape of flammable vapors, which is especially critical in open-topped tanks, enhancing safety while maintaining accurate liquid level measurement.

Advantages and Disadvantages of Bubbler Level sensor

Maintenance Considerations

Although air bubbler systems are relatively simple in principle, they do include several moving parts that require regular maintenance. Key components include valves that control the flow of gas to the tank and actuators that operate these valves. Additionally, compressors and other electro-mechanical devices are integral to maintaining a consistent air or nitrogen supply. Regular inspection and servicing of these components are essential to ensure reliable liquid level measurement and prevent system downtime.

Safety Advantages

One significant advantage of air bubbler systems is that most maintenance tasks can be performed away from the tank itself, minimizing the maintenance worker’s exposure to hazardous or flammable liquids such as gasoline. This remote maintenance capability enhances operator safety while reducing the risk of accidents during routine servicing.

Operational and Legacy Challenges

Air bubbler systems are not without limitations. A sudden loss or drop in bubbler pressure can lead to reduced measurement accuracy or even complete system failure. Furthermore, these systems face a legacy issue: as many air bubbler models are being phased out, the availability of replacement parts is diminishing. Components that were once standard are now becoming scarce, making maintenance increasingly challenging and sometimes costly.

Despite these challenges, air bubbler systems remain a robust solution in applications where other level measurement techniques may fail due to sediments, turbulence, or aggressive chemicals.

Read Next: