A PSV P&ID (Pressure Safety Valves P&ID) is a vital engineering document that illustrates how pressure safety valves and pressure relief devices are connected within a process system. In process industries, a well-prepared PSV or PRV P&ID clearly defines overpressure protection philosophy, showing safety valve symbols, inlet and outlet connections, and discharge routing. Accurate representation of PSVs, PRVs, and relief valves in a P&ID is essential for plant safety, regulatory compliance, and smooth operations.

What is a Pressure Safety Valve (PSV)?

A Pressure Safety Valve (PSV), often referred to as a pressure relief valve in general discussions, is a mechanical device designed to automatically release excess pressure from equipment when the pressure exceeds a safe limit. In engineering drawings such as a pressure relief valve P&ID or PRV P&ID, the PSV is shown as a mandatory safety element connected to the protected system.

PSVs are commonly installed on:

- Pressure vessels

- Pipelines

- Heat exchangers

- Boilers and steam headers

Importance of PSV P&ID in Process Design

The PSV P&ID or P&ID PRV acts as the master reference document during:

- Process design and detailed engineering

- HAZOP and safety reviews

- Installation and commissioning

- Operation and maintenance

Any mistake in a PSV P&ID or relief valve P&ID can result in improper installation, unsafe operation, or non-compliance with statutory requirements.

PSV and PRV Symbols in P&ID

Relief Valve and Safety Valve Symbols

In a PSV P&ID or PRV P&ID, pressure safety valves are represented using standardized safety valve symbols as per ISA or ISO conventions. These symbols are often grouped under relief valve P&ID symbols and clearly distinguish safety devices from control valves or regulators.

Guidelines

- Use consistent safety valve symbol representation across all drawings

- Clearly differentiate:

- PSV

- PRV

- Pressure relief valve

- Avoid confusion with P&ID pressure regulator symbols

PSV Tagging and Identification in P&ID

Each valve shown in a Pressure Safety Valves P&ID or pressure relief valve P&ID must have a unique tag number.

Typical Tag Example

PSV-101A

Tagging rules apply equally to:

- PSV P&ID

- PRV P&ID

- Relief valve P&ID

The tag number must match datasheets, line lists, and relief valve sizing calculations.

PSV Location and Inlet Connection Guidelines

In a Pressure Safety Valves P&ID, the inlet connection must be shown directly on the protected equipment or pipeline.

Key Rules

- Inlet piping should be short and straight

- Avoid unnecessary fittings or restrictions

- If isolation valves are shown:

- They must be locked or car-sealed open

- This condition should be noted on the P&ID PSV

PSV Discharge Piping in P&ID

A PSV P&ID or relief valve P&ID must clearly show where the relieved fluid is discharged.

Common Discharge Routes

- Flare header

- Closed vent system

- Safe atmospheric location

Best Practices

- Clearly label discharge lines (e.g., To Flare)

- Use flow direction arrows

- Do not terminate discharge lines ambiguously

PSV with Rupture Disk Representation

When rupture disks are installed along with PSVs, the configuration must be clearly shown in the Pressure Safety Valves P&ID or pressure relief valve P&ID.

Guidelines

- Show rupture disk using a separate symbol

- Indicate whether it is upstream or downstream of the PSV

- Add notes for burst pressure or monitoring connections

Instrumentation and Regulators in PSV P&ID

Depending on design philosophy, the Pressure Safety Valves P&ID may also show:

- Pressure gauges near the PSV inlet

- Pressure transmitters

- Drain and vent connections

Care must be taken not to confuse safety devices with P&ID pressure regulator symbols, as regulators perform control functions and not overpressure protection.

Applicable Codes Referenced in PSV and PRV P&ID

Although calculations are not included, Pressure Safety Valves P&IDs often reference applicable standards such as:

- ASME Section VIII

- API 520 and API 521

- ISO 4126

These references apply equally to Pressure Safety Valves, PRV, and pressure relief valve P&ID documentation.

Multiple PSVs in a Single P&ID

When more than one safety valve protects the same equipment:

P&ID Guidelines

- Show each PSV separately with unique tags

- Clearly indicate parallel installation or switching arrangements

- Maintain clarity between multiple safety valve symbols

Do’s and Don’ts for PSV and Relief Valve P&ID

Do’s

- Use standard relief valve P&ID symbols

- Keep tagging consistent across PSV and PRV P&IDs

- Clearly show inlet and discharge routing

- Maintain consistency between Pressure Safety Valves PSV and datasheets

Don’ts

- Do not mix safety valve symbols with pressure regulator symbols

- Do not omit discharge destinations

- Do not overcrowd the Pressure Safety Valves P&ID with construction details

Pressure Safety Valve P&ID – Summary

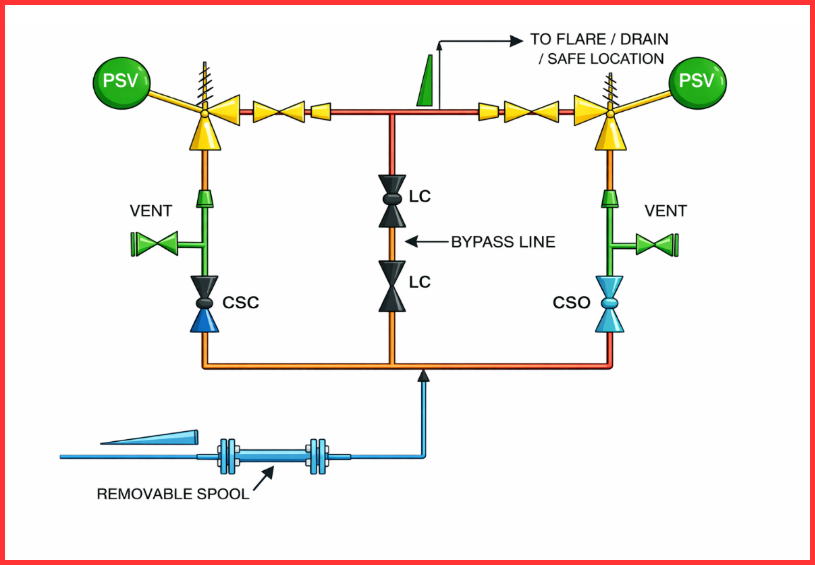

- A Pressure Safety Valve P&ID represents the standard arrangement of safety or relief valves used for overpressure protection in process systems.

- Correct safety valve symbols are selected as per project P&ID standards to clearly differentiate PSVs from control valves and pressure regulators.

- For critical equipment that cannot be isolated without plant shutdown, a spare pressure safety valve is typically provided and shown on the P&ID.

- Changes in inlet and outlet nozzle sizes are clearly indicated using reducers and expanders to reflect actual piping conditions.

- Block valves are provided upstream and downstream of the PSV for maintenance, with duty valve isolations shown as locked or car-sealed open.

- A vent valve is commonly installed between the upstream block valve and the PSV to allow safe depressurization during maintenance.

- Bypass lines may be included for start-up or process requirements, depending on project standards.

- PSV discharge routing is clearly shown, directing flow to a flare system, drain system, or a safe atmospheric location based on service conditions.

- Inlet piping is sloped toward the protected equipment, while outlet piping is sloped toward the flare header or safe discharge point.

- For PSVs connected to flare systems, an inlet spool piece is generally provided to simplify valve removal and maintenance.

- These Pressure Safety Valve P&ID practices are general guidelines and may be adapted to meet project-specific and code requirements.

Conclusion

A clear and well-structured PSV P&ID is essential for safe and compliant plant operation. By correctly applying relief valve P&ID symbols, safety valve symbols, proper tagging, and clear discharge routing, engineers ensure effective overpressure protection. Whether it is a Pressure Safety Valves P&ID, PRV P&ID, or pressure relief valve P&ID, following standardized guidelines helps improve safety, simplify reviews, and support reliable plant operation throughout its lifecycle.

Read Next: