Bubble tube level measurement is a reliable and widely used method for measuring liquid level in tanks, pits, and open channels. It is especially effective in harsh environments where corrosive, dirty, or slurry-type fluids make direct contact sensors unreliable. This technique works on a simple pressure principle and is also commonly known as bubbler level measurement.

In this article, you will learn the bubble tube level measurement principle, its working, components, advantages, limitations, and real-world applications.

What Is Bubble Tube Level Measurement?

Bubble tube level measurement is an indirect level measurement method that determines liquid level by measuring the air pressure required to force bubbles out of a submerged tube. The pressure inside the tube is directly proportional to the height of the liquid column above the tube opening.

This system is also referred to as:

- Bubbler level

- Bubbler gauge

- Air bubble level

- Level measurement bubbler

Bubble Tube Level Measurement Principle

Bubbler systems operate on the hydrostatic pressure principle and are widely used for level measurement in vessels and tanks operating under atmospheric pressure.

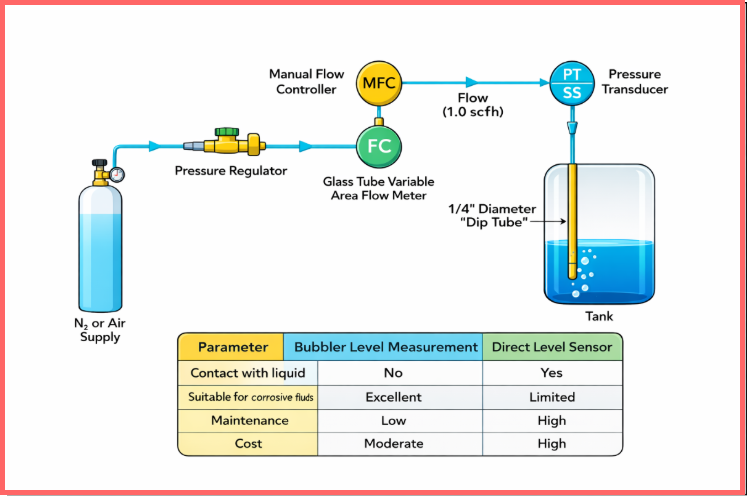

In this method, a dip tube is installed with its open end positioned near the bottom of the vessel. A controlled flow of purge gas is introduced into the tube. Typically, compressed air is used; however, inert gases such as dry nitrogen are selected when there is a risk of oxidation, contamination, or chemical reaction with the process fluid.

As air flows through the immersed tube, pressure builds up inside the dip tube. When the liquid level rises, the air pressure required to release bubbles from the tube outlet increases. Conversely, when the liquid level falls, the required air pressure decreases.

The pressure needed to continuously form bubbles at the tube opening is equal to the hydrostatic head pressure created by the liquid column above the tube tip. This pressure—directly proportional to the liquid density and level height—is sensed by a connected pressure transducer and converted into an accurate level signal.

Mathematical Representation:

P=ρgh

Where:

- P = Pressure in the bubbler tube

- ρ = Density of the liquid

- g = Acceleration due to gravity

- h = Height of liquid above the tube tip

By measuring this pressure, the liquid level can be accurately determined.

Working of Bubbler Tube Level Measurement

The working of bubbler tube level measurement follows these steps:

- A regulated air supply is connected to a dip tube.

- The tube is inserted into the tank until it reaches near the bottom.

- Air flows continuously through the tube at a low, controlled rate.

- Bubbles escape from the open end of the tube.

- The back pressure builds up inside the tube.

- This pressure equals the liquid head pressure.

- A bubbler level transmitter measures this pressure.

- The transmitter converts pressure into a level signal.

Because the tube never fills with liquid, the sensor remains isolated from the process.

Main Components of a Bubbler Level Measurement System

A typical bubbler tube level measurement system consists of the following components, each playing a vital role in accurate and stable level indication:

- Air Supply

The air supply provides clean, dry compressed air or an inert gas such as nitrogen at a constant pressure. The quality of the supplied gas is critical, as moisture, oil, or contaminants can clog the tubing and affect measurement accuracy. In applications involving corrosive or reactive liquids, inert gas is preferred to prevent chemical reactions or contamination of the process fluid. - Flow Regulator

The flow regulator controls the amount of air entering the bubbler tube and ensures a steady, low-rate flow. Proper regulation allows continuous bubbling at the tube outlet without excessive air consumption. A stable airflow is essential to maintain consistent pressure inside the tube, which directly reflects changes in liquid level. - Dip Tube (Bubbler Tube)

The dip tube is a vertical pipe installed inside the vessel with its open end positioned near the bottom. Air passes through this tube and exits as bubbles into the liquid. The pressure inside the tube rises or falls based on the liquid height above the tube opening, making it the primary sensing point of the system. - Pressure Transmitter

The pressure transmitter, commonly referred to as a bubbler level transmitter, measures the back pressure developed in the dip tube. This pressure is proportional to the hydrostatic head of the liquid. The transmitter converts the measured pressure into a standard electrical signal, such as 4–20 mA, for transmission to indicators, controllers, or distributed control systems. - Pressure Gauge (Optional)

A pressure gauge may be installed in the system to provide a local visual indication of pressure and corresponding liquid level. Often called a bubbler gauge, it allows operators to quickly verify system operation and level trends without relying solely on electronic instrumentation.

Types of Bubbler Tube Level Measurement Systems

- Constant Flow Bubbler

In this type, a continuous and fixed airflow is supplied through the bubbler tube at all times. The steady flow ensures consistent bubble formation at the tube outlet, resulting in stable pressure buildup inside the tube. Because of its simplicity, reliability, and accurate response to level changes, this is the most commonly used bubbler level measurement arrangement in industrial applications. - Intermittent Bubbler

In an intermittent bubbler system, air is introduced into the tube at regular intervals rather than continuously. The pressure is measured only during the air release cycle. This approach significantly reduces air consumption and is suitable for applications where continuous level monitoring is not required or where compressed air availability is limited. - Differential Pressure Bubbler

This configuration uses differential pressure measurement to determine liquid level, making it suitable for applications where liquid density may vary. By compensating for density changes, the system provides more accurate level readings in processes involving temperature fluctuations, concentration changes, or mixed fluids.

Advantages of Bubble Tube Level Measurement

Bubble tube level measurement offers several practical benefits:

- No direct contact between sensor and liquid

- Ideal for corrosive and dirty fluids

- Simple design and low maintenance

- Works well in open tanks and sumps

- Suitable for high-temperature liquids

- Long service life

Limitations of Bubbler Level Measurement

Despite its advantages, bubbler level measurement has some limitations:

- Requires a continuous air supply

- Accuracy depends on liquid density

- Not ideal for pressurized vessels

- Air bubbles may disturb sensitive processes

Applications of Bubbler Level Measurement

Bubbler tube level measurement is widely used in industrial processes such as:

- Wastewater treatment plants

- Chemical storage tanks

- Slurry and mud tanks

- Acid and alkali storage

- Open channels and sumps

- Effluent monitoring systems

It is particularly effective where ultrasonic or radar sensors fail.

Difference Between Bubbler Tube Level Measurement and Direct Level Sensors

| Parameter | Bubbler Level Measurement | Direct Level Sensor |

| Contact with liquid | No | Yes |

| Suitable for corrosive fluids | Excellent | Limited |

| Maintenance | Low | High |

| Cost | Moderate | High |

Conclusion

Bubble tube level measurement is a proven and dependable technique for liquid level monitoring in challenging industrial environments. By using air pressure instead of direct contact, bubbler level measurement ensures safety, durability, and consistent performance. Whether referred to as a bubbler level transmitter, bubbler gauge, or air bubble level, this method remains a preferred solution for reliable level measurement in harsh conditions.

Read Next: