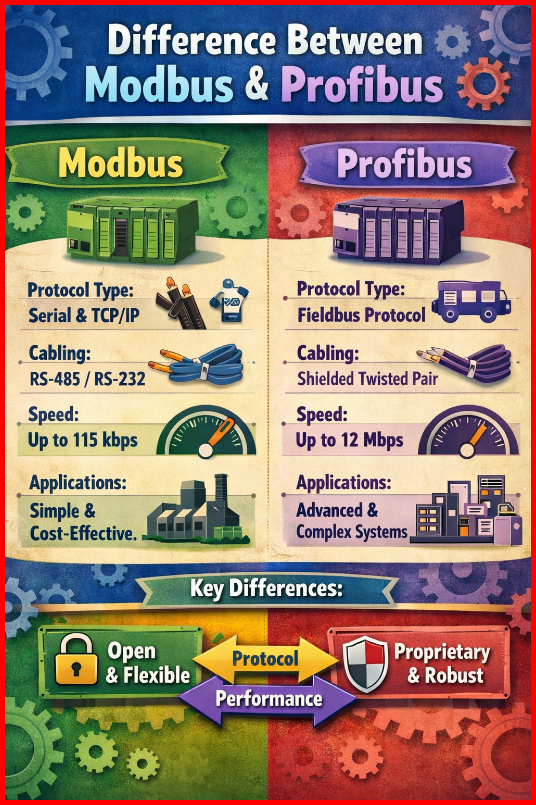

The main difference between Modbus and Profibus is their level of complexity and performance. Modbus is a simple, open, and low-cost communication protocol used for basic industrial data exchange. In contrast, Profibus is a high-speed, deterministic fieldbus designed for complex and real-time industrial automation systems.

This clear difference between Modbus and Profibus helps engineers select the right protocol based on application requirements.

What is Modbus?

Modbus is a widely used industrial communication protocol originally developed by Modicon, a company that later became part of Schneider Electric. The protocol gets its name from this origin. Modbus follows a client-server (master-slave) communication model, where one master device initiates communication by requesting data, and the slave devices respond with the requested information.

The Modbus meaning refers to a simple and reliable messaging structure that enables devices such as PLCs, HMIs, energy meters, and SCADA systems to exchange data efficiently.

Modbus is primarily based on serial communication, where data is transmitted one bit at a time. Due to this nature, serial communication is generally slower than parallel communication, but it is highly reliable and well-suited for industrial environments. Modbus can operate over physical interfaces such as RS-232, RS-485, and Ethernet, making it flexible for various applications.

Communication Formats in Modbus

Modbus supports multiple data formats, each designed for specific use cases:

- Modbus RTU – Uses binary data over serial links, offering faster and more efficient communication

- Modbus ASCII – Transmits data in ASCII text format, making it easier to read and troubleshoot

- Modbus TCP/IP – Runs over Ethernet networks and is commonly used in modern automation systems

Key Characteristics of Modbus

- Open and royalty-free protocol

- Simple configuration and easy troubleshooting

- Supports both serial and Ethernet communication

- Widely supported by devices from different manufacturers

Modbus works on a master-slave architecture, meaning only the master can initiate communication. A standard Modbus network can support up to 247 slave devices, each identified by a unique unit ID. Communication is structured using elements such as function codes, register or coil addresses, and read/write commands.

To ensure data integrity, Modbus uses Cyclic Redundancy Check (CRC) error detection. Two CRC bytes are appended to every Modbus message, allowing the receiving device to detect transmission errors and maintain reliable communication.

Typical Applications of Modbus

- Energy and power monitoring systems

- PLC to HMI communication

- SCADA and data acquisition systems

- Simple and cost-effective industrial automation

Modbus vs RS485

The comparison Modbus vs RS485 is often misunderstood. Modbus is a protocol, while RS485 is a physical communication standard. Modbus RTU commonly uses RS485, but RS485 itself does not define communication rules

What is Profibus?

Profibus (Process Field Bus) is an industrial fieldbus communication protocol developed by Siemens for fast, reliable, and deterministic data exchange in automation systems. It is designed to handle complex industrial environments where real-time communication between controllers and field devices is critical. Compared to simpler protocols like Modbus, Profibus offers higher speed, better synchronization, and advanced diagnostics.

The Profibus meaning refers to a standardized field-level communication network that ensures precise and real-time data transfer between PLCs, sensors, actuators, drives, and process instruments. Its deterministic nature guarantees predictable response times, which is essential in industrial automation.

Types of Profibus

Profibus is available in two main variants, each optimized for specific applications:

- Profibus DP (Decentralized Peripherals)

Used in factory and machine automation for high-speed communication with sensors, actuators, and drives. - Profibus PA (Process Automation)

Designed for process industries such as chemical and oil & gas plants, including operation in hazardous areas.

These variants include application-specific features, allowing engineers to select the appropriate protocol based on system requirements.

Key Characteristics of Profibus

- High data transmission speed

- Deterministic and real-time communication

- Advanced diagnostics and fault detection

- Supports large and complex industrial networks

Profibus communication is primarily based on RS-485, unlike Modbus, which can operate over multiple physical layers.

Multi-Master Communication in Profibus

One of the defining features of Profibus is its multi-master capability. Multiple master devices can exist on the same network and share control using a token-passing mechanism. Each master performs a startup sequence (cold or warm start) before participating in communication.

Slave devices respond only when requested by a master. If no request is received within a specified time, a slave enters a standby state until communication is reinitiated. This structured approach ensures that all masters and slaves remain synchronized and available for reliable data exchange.

(Note: Multi-master operation is typically associated with Profibus systems used in advanced automation setups.)

Profibus Profinet Difference

When discussing the Profibus Profinet difference:

- Profibus uses serial communication, mainly over RS-485

- Profinet is based on Industrial Ethernet

- Profinet provides greater flexibility, higher scalability, and easier integration with modern networks

Key Differences Between Modbus and Profibus

- Protocol Accessibility

Modbus is an open and royalty-free communication protocol that can be implemented by any manufacturer. Profibus, on the other hand, follows controlled specifications and is not freely available for unrestricted use. - Developer Origin

Modbus was introduced by Schneider Electric (originally Modicon), while Profibus was developed by Siemens for industrial automation systems. - Protocol Variants

Modbus primarily operates in two formats—Modbus RTU and Modbus ASCII. Profibus is available in two specialized versions: Profibus DP for factory automation and Profibus PA for process industries. - Communication Speed

Profibus supports significantly higher data transfer rates, making it suitable for time-critical and real-time automation tasks. Modbus offers lower to moderate speeds, adequate for basic data exchange. - Physical Communication Layer

Modbus can function over multiple physical layers such as RS-232, RS-485, and Ethernet. Profibus communication is mainly limited to RS-485. - Master Configuration

Modbus uses a single-master architecture, where only one device controls communication. Profibus supports multi-master operation, allowing multiple controllers to share the same network. - Ease of Implementation

From a programming and configuration perspective, Modbus is simpler and quicker to deploy. Profibus requires more detailed setup and configuration. - Network Capability

Profibus is better suited for large and complex industrial networks, offering higher efficiency and stability. Modbus is ideal for smaller and less complex systems. - Diagnostics and Troubleshooting

Profibus includes advanced diagnostic and monitoring features that simplify fault detection. Modbus provides only basic diagnostic capabilities.

Modbus vs Profibus( Tabular Comparision)

The table below summarizes the difference between Modbus and Profibus without overlap or repetition:

| Feature | Modbus | Profibus |

| Year & Origin | Developed by Modicon (Schneider Electric) in the late 1970s | Developed by Siemens in the late 1980s under European fieldbus standards |

| Protocol Nature | Simple, open, and easy to implement | Advanced industrial fieldbus |

| Communication Model | Client–server (single master) | Multi-master with token passing |

| Supported Variants | RTU, ASCII, TCP/IP | Profibus DP and Profibus PA |

| Physical Layer | RS-232, RS-485, Ethernet | Primarily RS-485 |

| Communication Speed | Low to medium (higher with TCP/IP) | High speed (up to 12 Mbps) |

| Real-Time Capability | Non-deterministic | Deterministic and real-time |

| Diagnostics | Basic error detection | Advanced diagnostics and fault analysis |

| Network Size | Best suited for small systems | Designed for large and complex networks |

| Typical Application | Basic automation and monitoring | Complex and time-critical automation |

| Cost & Complexity | Low cost and simple to implement | Higher cost with more complex setup |

This comparison clearly explains modbus vs profibus in practical terms.

Profibus versus Modbus: Which One to Use?

The choice between profibus or modbus depends on system requirements.

- Modbus is suitable for small systems where simplicity and cost are priorities.

- Profibus is preferred in environments requiring fast response, real-time control, and detailed diagnostics.

In essence, profibus vs modbus reflects a trade-off between performance and simplicity.

CAN vs Modbus (Brief Comparison)

In CAN vs Modbus, CAN is event-driven and commonly used in automotive and embedded systems, while Modbus is request-response based and widely used in industrial monitoring and control.

Conclusion

The Difference Between Modbus and Profibus lies mainly in performance, scalability, and application scope. Modbus offers simplicity and ease of use, making it ideal for basic industrial communication. Profibus provides high-speed, deterministic communication suited for advanced automation systems.

When selecting between modbus and profibus, understanding this difference between Modbus and Profibus ensures reliable communication, better system design, and long-term operational efficiency.

Read Next: