Measuring fluid flow accurately is essential in process industries, and the orifice plate remains one of the most trusted flow-measurement devices worldwide. However, the accuracy of any orifice-based flow meter depends heavily on one factor: the location of the pressure tappings. These pressure points, known as orifice plate tapping, determine how precisely the differential pressure across the orifice is captured.

In this article, we’ll break down the concept of Orifice Plate Tapping, different types of orifice plate taps, and when to use corner tapping, flange tapping, and other pressure tappings used in industrial applications.

What is Orifice Plate Tapping?

Orifice plate tapping refers to the exact points on the pipeline where pressure tappings or pressure ports are installed to measure the pressure difference caused by an orifice plate. This differential pressure is then used to calculate flow rate.

Selecting the wrong tapping method can lead to inaccurate readings, while the correct tapping plate layout ensures consistent and reliable flow measurement.

Types of Orifice Plate Taps

Different standards recommend different tap positions depending on the application, fluid type, accuracy requirements, and installation constraints. The most widely used orifice plate tappings include:

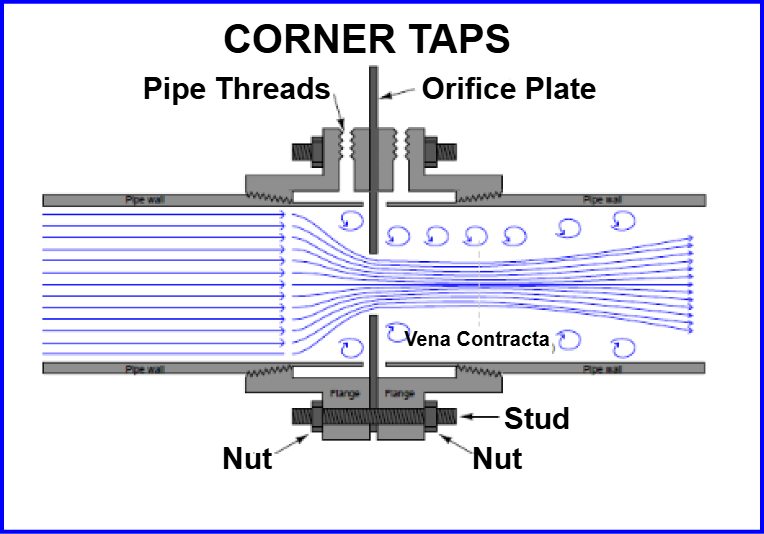

1. Corner Tapping (Corner Taps)

Corner tapping is one of the most widely used methods for orifice plate flow measurement, especially in Europe and Asia. In this setup, the pressure taps sit directly at the upstream and downstream faces of the orifice plate, right where the plate touches the pipe wall. This placement helps the taps sense the pressure as close as possible to the point of flow contraction.

Corner taps work best in small pipe sizes. In such pipes, the vena contracta forms very close to the downstream face of the orifice plate. If you install flange taps in this situation, they will fall inside the turbulent region right after the vena contracta. As a result, they pick up unstable pressure signals and reduce measurement accuracy. Corner taps avoid this issue by taking pressure readings from a more stable point.

However, corner tapping needs special flange fittings, which usually cost more than standard ones. Because of this, engineers prefer corner taps only when the small pipe size or accuracy requirement justifies the extra cost.

Regardless of the tapping method, you must ensure the tap holes remain completely flush with the inner pipe surface. Even a tiny burr, recess, or mismatch from drilling can disturb the pressure and introduce errors. For this reason, manufacturers usually drill these holes in controlled shop environments where they can maintain high precision. Field drilling often lacks this level of accuracy.

To prevent tapping inside a turbulent zone, some standards—like the pipe-tap or full-flow tap configuration—place the downstream tap eight pipe diameters away from the orifice plate. This extra distance gives the flow enough space to stabilize before the pressure is measured.

In short, corner taps offer excellent accuracy for small-diameter pipes, provided the installation is precise and the tap holes meet high-quality standards.

Applications of Corner Taps

- Low to medium line sizes

- Clean liquids and gases

- Installations following ISO 5167 standards

Advantages

- High accuracy for small-diameter pipes

- Easy installation

- Minimal tapping errors

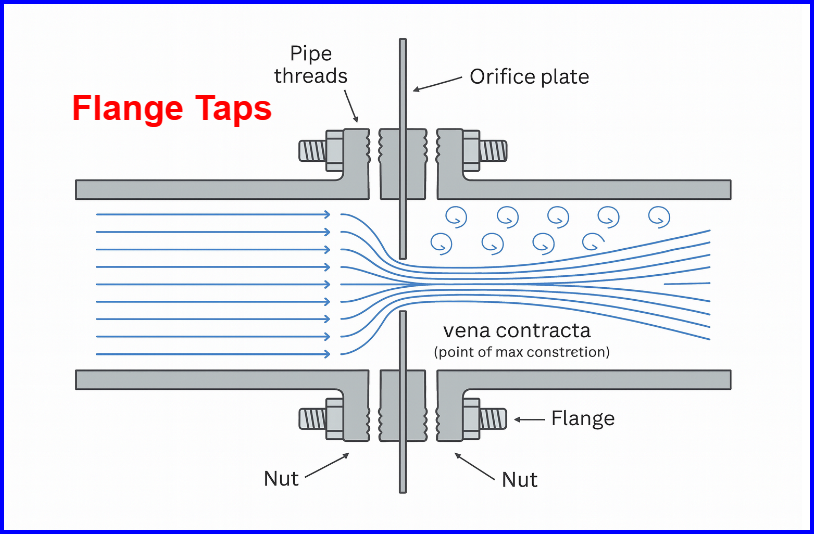

2. Flange Tapping (Flange Taps)

When an orifice plate is installed in a vertical pipeline, the flow usually moves upward—from the bottom toward the top. In this arrangement, the lower tap functions as the high-pressure point, while the upper tap becomes the low-pressure point. Because this system handles liquid, technicians place the transmitter below the tapping points to prevent air or gas bubbles from collecting in the impulse lines.

A better installation keeps all impulse lines below or level with the tap connections on the liquid-filled pipe so that no gas pockets can form.

Flange tapping is the most popular tapping style in the United States and is widely specified in ASME standards.

In flange taps, pressure points are drilled 25.4 mm (1 inch) upstream and downstream from the orifice plate along the flanges.

Advantages of Flange Taps

- Simple maintenance

- Best suited for standard orifice meters

- Very common in oil & gas pipelines

Where Flange Tapping Is Used

- Medium to large pipelines

- Custody-transfer applications

- Orifice meters with orifice fittings

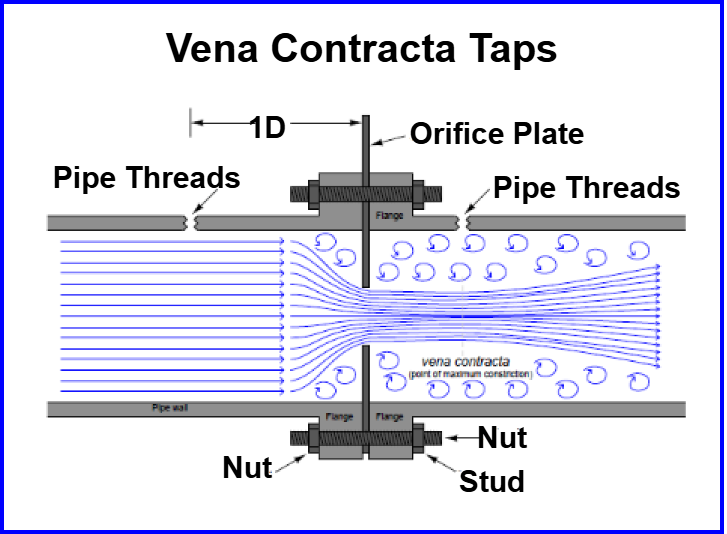

3. D-D/2 Tapping-Vena contracta taps

Vena contracta taps generate the highest differential pressure for a given flow rate, which makes them extremely sensitive and accurate. However, they demand precise engineering because the downstream tap must be positioned at exactly the right spot where the vena contracta forms. A slight miscalculation can shift the tap into a turbulent region and compromise the measurement.

For large pipeline diameters, engineers often use radius taps as a practical alternative. In this method, the downstream (low-pressure) tap is placed at approximately half the pipe diameter downstream—a simplified approximation of the true vena contracta location.

Both tap types share a major drawback: they require drilling directly into the pipe wall. This not only reduces the structural integrity of the pipe but also increases the risk of errors. Because these holes are usually drilled on-site rather than in a controlled factory environment, variations in alignment, burrs, and rough surfaces can easily occur, all of which affect measurement accuracy.

This tapping method positions:

- Upstream tap at 1 pipe diameter (D)

- Downstream tap at ½ pipe diameter (D/2)

These taps capture pressure close to the vena contracta, the point where fluid velocity peaks.

Applications

- High-accuracy liquid measurements

- Situations with fluctuating flow

Benefits

- More stable differential pressure readings

- Suitable for viscous fluids

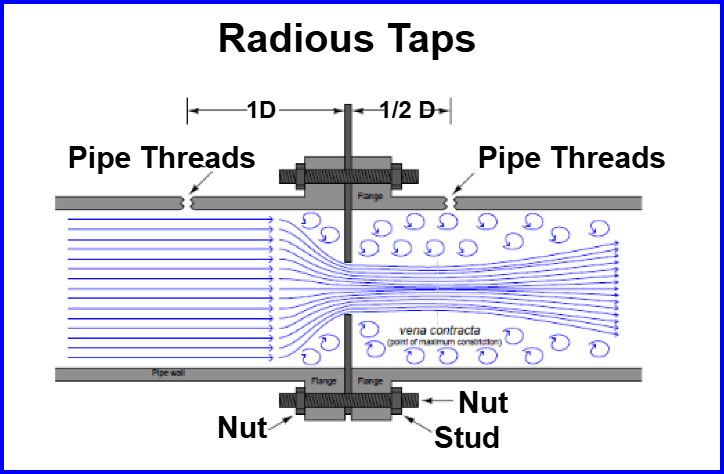

4. Radius Tapping

Radius tapping is a widely used method for measuring differential pressure across an orifice plate. In this setup, the upstream tap sits one pipe diameter (1D) from the plate, while the downstream tap is positioned at half a pipe diameter (0.5D). This arrangement strikes a smart balance: it delivers strong measurement accuracy by coming close to the vena contracta location, yet avoids the unstable flow region immediately behind the orifice. Radius taps work especially well on larger pipelines, where the flow tends to stabilize more quickly.

How Radius Tapping Works

- Upstream Tap (1D): Installed one pipe diameter upstream of the orifice plate, capturing stable pressure before the flow begins to contract.

- Downstream Tap (0.5D): Positioned half a pipe diameter downstream, close to where the vena contracta forms but safely outside the chaotic zone right after the plate.

- Purpose: This tap spacing allows the transmitter to measure a clean, reliable pressure differential without interference from turbulence.

Key Benefits of Radius Taps

- Practical and Easy to Install: The fixed 0.5D position simplifies installation compared to true vena contracta taps, which require exact calculations and precise placement.

- Good Accuracy: Provides a close approximation to vena contracta tapping, making it suitable for many industrial flow measurement applications.

- Versatile in Large Pipelines: Performs particularly well in bigger pipes where the flow profile is smoother and easier to predict.

5. Pipe Tap Tapping (Pipe Taps)

Pipe taps in an orifice plate setup use pressure measurement points placed far from the restriction—2.5 pipe diameters upstream and 8 pipe diameters downstream. This tapping method captures the overall pressure loss in the pipeline, not just the drop across the orifice plate.

It’s easy to install on existing pipelines but delivers lower accuracy compared to flange taps or vena contracta taps. Because the taps sit well outside turbulent zones, they provide more stable readings, though the long spacing can introduce additional uncertainty. For this reason, pipe taps are best suited for general flow monitoring, not high-precision metering.

How Pipe Taps Work with an Orifice Plate

- Working Principle:

The orifice plate creates a restriction that increases velocity and reduces pressure. A differential pressure transmitter reads the pressure difference between the two pipe tap locations to estimate flow. - Tap Location:

- Upstream tap: 2.5D (D = pipe diameter) before the orifice

- Downstream tap: 8D after the orifice

- What They Measure:

These taps capture the entire pressure drop over the larger pipe section, including the orifice plate’s loss and additional friction losses. - Accuracy Consideration:

Since the taps do not measure the maximum pressure drop near the vena contracta, the flow calculation is less accurate. - Best Application:

Ideal for pipelines where installing flange taps isn’t feasible or where the system only needs rough flow indication, not precise metering.

Use Cases

- Large-diameter pipelines

- Systems with high turbulence

Why Tap Location Matters

Proper tap selection ensures:

- Accurate flow measurement

- Reduced uncertainty

- Compliance with standards (ISO/ASME)

- Lower long-term maintenance

Using the wrong tapping plate layout can lead to:

- Incorrect DP measurements

- Flow calculation errors

- Energy losses

Orifice Fitting and Tapping Plate Assembly

In advanced systems, the orifice plate is mounted inside an orifice fitting, a device that allows technicians to change or clean the orifice plate without stopping the pipeline. These fittings include:

- Integrated tapping flanges

- Pre-machined pressure tappings

- Seals and clamping mechanisms

This setup is ideal for pipelines requiring continuous flow, as found in refineries and gas distribution networks.

Comparison of Orifice Plate Tapping Methods

| Tapping Type | Upstream Position | Downstream Position | Accuracy | Best For |

| Corner Taps | At plate corner | At plate corner | High | Small pipes, ISO systems |

| Flange Taps | 1 inch from plate | 1 inch from plate | High | ASME systems, oil & gas |

| D-D/2 Taps | 1D | 0.5D | Very High | Liquids, fluctuating flow |

| Radius Taps | 1R | 0.5R | Moderate-High | Steam, gas |

| Pipe Taps | 2.5D | 8D | Moderate | Large pipelines |

Conclusion

Orifice plate tapping plays a crucial role in determining the accuracy and reliability of flow measurement systems. Whether you choose corner tapping, flange tapping, or advanced pressure tappings, the goal is to capture the most stable differential pressure across the tapping plate.

Each tapping method has its own advantages and best-use scenarios. When combined with a high-quality orifice fitting and proper installation, these taps can provide highly accurate and efficient flow monitoring across all industries.

Read Next: