Siemens PLCs are among the most widely used programmable logic controllers in the world. From small machines to large industrial plants, Siemens offers PLC solutions for almost every automation requirement. In this article, we provide a clear and practical overview of Siemens PLC systems, focusing on S7-1200, S7-1500, S7-300, S7-400, and S7-ET 200 PLCs.

This overview covers only a small portion of Siemens’ vast industrial automation portfolio, but it will help you understand which PLC fits which application.

Siemens in Industrial Automation

Siemens is a global leader in industrial automation technology. Founded in 1847, the company operates in multiple sectors, including:

- Industrial automation

- Energy and power systems

- Transportation

- Healthcare

- Digital industries

In automation, Siemens is known for reliable hardware, powerful software, and long product life cycles.

Key Siemens automation solutions include:

- Programmable Logic Controllers (PLCs)

- Human Machine Interfaces (HMIs)

- Variable Frequency Drives (VFDs)

- Industrial communication networks

- Automation software

A major strength of Siemens is Totally Integrated Automation (TIA), where all automation components work seamlessly together.

Siemens Different PLC Families

Siemens developed two major PLC families over time:

Simatic S5 PLC Family

- Older generation PLCs

- Still found in legacy plants

- No longer manufactured

Simatic S7 PLC Family

- Current and actively supported PLC family

- Widely used across industries

- Highly scalable and modular

The Simatic S7 family is the focus of modern Siemens automation systems.

Overview of Siemens S7 PLC

The Siemens S7 PLC platform includes multiple sub-families, each designed for specific automation needs. These PLCs differ in:

- Processing power

- Memory size

- Communication capabilities

- Safety features

- Application complexity

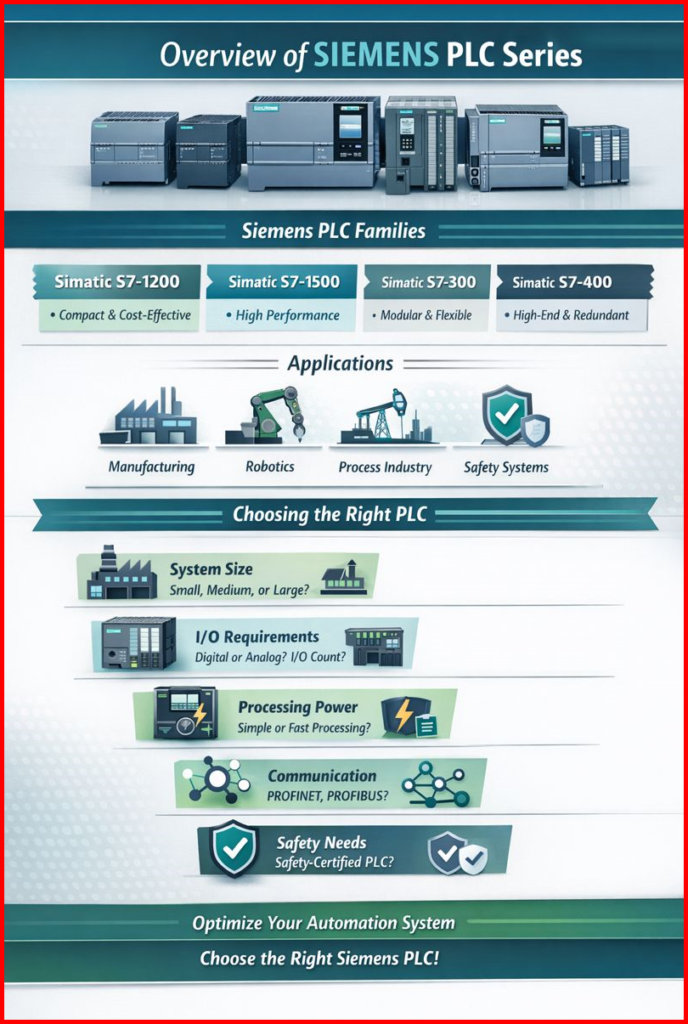

The main Siemens S7 PLC families are:

- Simatic S7-1200

- Simatic S7-1500

- Simatic S7-300

- Simatic S7-400

- Simatic S7-ET 200

Simatic S7-1200

The Simatic S7-1200 is a compact and cost-effective PLC designed for small to medium-scale automation.

Key Features

- Compact design

- Integrated I/O

- Built-in PROFINET

- High performance for small machines

Typical Applications

- Packaging machines

- Conveyors

- Pumps and compressors

- Building automation

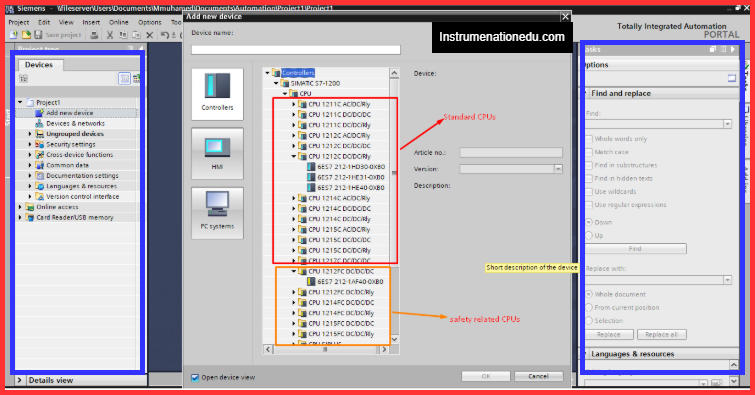

S7-1200 PLC Variants

- Standard CPUs (1211C to 1217C)

- Safety Integrated CPUs

- SIPLUS (harsh environment) versions

Simatic S7-1500

The Simatic S7-1500 is a high-performance PLC designed for advanced and large-scale automation systems.

Key Features

- Very fast processing speed

- Large program and data memory

- Advanced diagnostics

- Integrated safety and motion control

Typical Applications

- Automotive production lines

- Process industries

- Robotics

- High-speed machinery

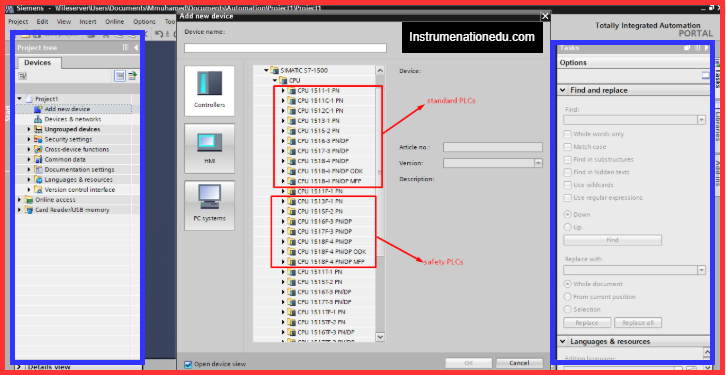

S7-1500 PLC Variants

- Standard CPUs

- Safety Integrated (F-CPU)

- Advanced Controllers

- Technology CPUs (T-CPU)

- AI and Machine Learning NPU modules

Simatic S7-300

The Simatic S7-300 is a modular PLC that has been widely used for many years.

Key Features

- Modular expansion

- Wide range of I/O modules

- Reliable and proven design

Typical Applications

- Manufacturing plants

- Material handling systems

- Batch processes

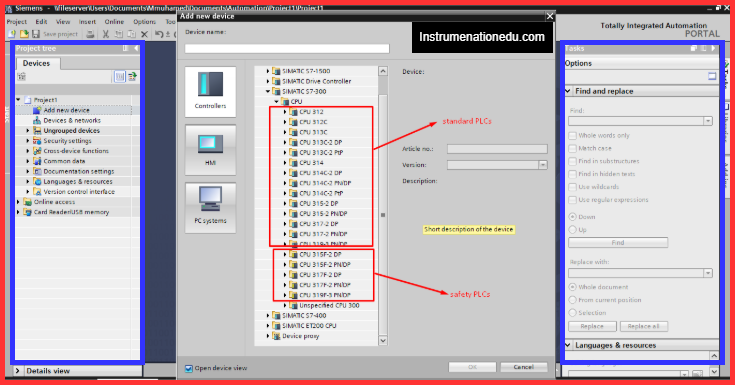

S7-300 PLC Variants

- Standard CPUs

- Fail-Safe CPUs

- Compact CPUs

- Technology CPUs

- Distributed controllers

Note: S7-300 is now considered legacy, but still operational in many plants.

Simatic S7-400

The Simatic S7-400 is designed for high-end and mission-critical automation.

Key Features

- Very high processing capability

- Large I/O capacity

- Redundancy options

- High availability

Typical Applications

- Power plants

- Oil and gas industries

- Large chemical plants

- Continuous process industries

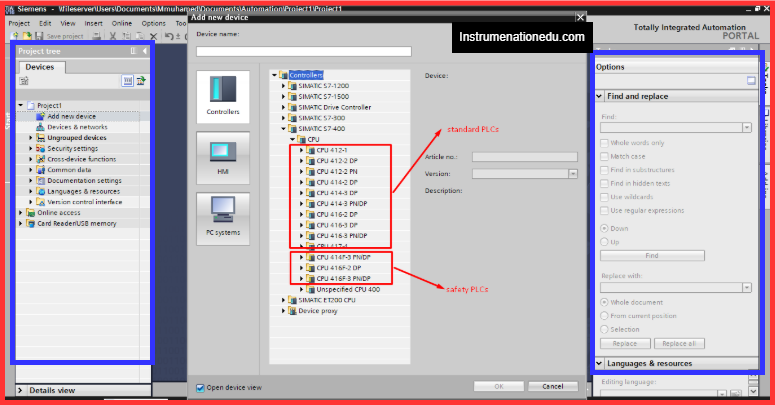

S7-400 PLC Variants

- Standard CPUs

- High-availability (H) CPUs

- Safety (F/FH) CPUs

- Distributed automation systems

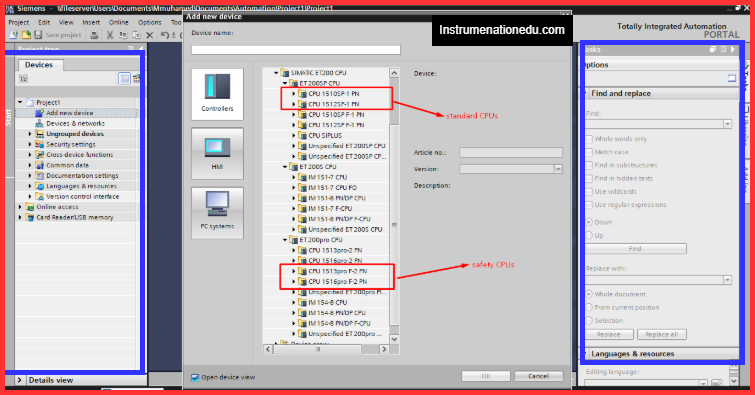

Simatic S7-ET 200 PLC

The Simatic S7-ET 200 combines PLC and distributed I/O in a compact design.

Key Features

- Small footprint

- High flexibility

- Integrated I/O

- PROFINET communication

Typical Applications

- Distributed automation

- Space-constrained panels

- Machine-level control

ET 200 PLC Variants

- Standard CPUs

- Safety CPUs

- ET 200SP compact CPUs

Why Are There So Many Different Siemens PLC Models?

Siemens offers many PLC models to meet different automation requirements, such as:

- Small vs large systems

- Simple vs complex processes

- Standard vs safety-critical applications

- Centralized vs distributed control

Different models provide different:

- Processing speeds

- Memory sizes

- Communication options

- I/O capacities

This allows engineers to select the most cost-effective and efficient PLC for each application.

How to Decide Which Type of S7 PLC Best Fits My Application?

Choosing the right Siemens PLC requires evaluating several technical factors.

Determine the Size and Complexity of Your Automation System

- Small machines → S7-1200

- Medium systems → S7-1500 or S7-300

- Large plants → S7-400

Identify the Required I/O Types and Count

- Digital I/O

- Analog I/O

- High-speed counters

- Special function modules

Ensure the PLC supports current and future expansion.

Consider the Required Processing Speed and Performance

- Simple logic → lower-end CPUs

- Motion control or fast cycles → high-performance CPUs

Evaluate the Required Communication Options

Common Siemens protocols include:

- PROFINET

- PROFIBUS

- Industrial Ethernet

- AS-Interface

Select a PLC with native support for your network.

Consider the Required Safety Features

If safety is required, choose:

- F-CPU versions

- Integrated safety I/O

- Certified safety communication

Conclusion

Siemens offers a powerful and flexible PLC portfolio through its Simatic S7 series, including S7-1200, S7-1500, S7-300, S7-400, and S7-ET 200 PLCs.

Each PLC family is designed to serve specific automation needs, from simple machines to large industrial plants. The availability of multiple models allows engineers to build scalable, safe, and high-performance automation systems.

Before selecting a Siemens PLC, always consider:

- System size

- I/O requirements

- Performance needs

- Communication protocols

- Safety requirements

Choosing the right PLC ensures reliable operation, lower costs, and future scalability.

Read Next: