A pressure switch is a mechanical or electronic device that activates when the pressure of a process fluid reaches a predefined threshold or setpoint. Its design can vary based on the sensing mechanism, which may include a Bourdon tube, piston, diaphragm, or membrane—each of which reacts to changes in system pressure by moving or deforming accordingly.

For instance, an air pressure switch is commonly used in compressor systems to maintain a stable pressure level. Once the air pressure inside the tank reaches the desired setpoint, the switch automatically shuts off the compressor. If the pressure drops below the required level, the switch re-engages the compressor to restore optimal pressure.

Key Components of a Pressure Switch

A pressure switch is composed of several essential components that work together to monitor and control pressure levels in a system. These components include:

- Diaphragm – The diaphragm is a flexible, pressure-sensitive element that detects changes in system pressure. Typically made from materials such as rubber, metal, or elastomers, it deforms in response to pressure variations, triggering the switch mechanism.

- Spring – The spring is crucial for setting the cut-in and cut-out pressure points. By adjusting the spring tension, users can define the pressure threshold at which the switch activates or deactivates, ensuring precise control of the system.

- Lever – The lever acts as the mechanical link between the diaphragm and the electrical contacts. When the diaphragm moves due to pressure changes, the lever either engages or disengages the switch, enabling or disabling the connected system component.

- Electrical Contacts – These metal connectors allow current to flow through the switch when it is activated. They control power transmission to external devices such as pumps, compressors, or alarms.

- Terminals – Terminals serve as the connection points for external wiring, linking the switch to the power source and the electrical load, ensuring seamless integration into the system.

Types of Pressure Switches

Pressure switches are broadly categorized into two main types: mechanical pressure switches and electronic pressure switches. Each type serves distinct applications depending on accuracy, durability, and control requirements.

1. Mechanical Pressure Switch

Mechanical pressure switches are rugged, reliable, and ideal for simpler applications. They function using a spring and piston mechanism to regulate the activation pressure. The spring counteracts the inlet pressure, and its tension is manually adjusted via a set screw or knob. The pretension of the spring determines the pressure level at which the switch triggers an electrical contact. Once the pressure drops below the setpoint, the switch resets to its default state.

A key advantage of mechanical pressure switches is their ability to handle higher voltages and amperages compared to electronic models. They are widely used in applications where direct contact control is necessary, such as pneumatic and hydraulic systems, water pumps, and industrial machinery.

2. Electronic Pressure Switch

Electronic pressure switches incorporate a pressure transducer, often a strain gauge, along with additional electronics that convert pressure variations into electrical signals. These switches offer superior accuracy, minimal contact wear, long-term stability, and the ability to perform thousands of switching cycles with high reliability.

Unlike mechanical switches, electronic models feature digital displays, programmable setpoints, and enhanced diagnostic capabilities, making them ideal for precision control applications in industries like automation, medical devices, and HVAC systems.

How Do Pressure Switches Work?

A pressure switch is a passive device, meaning it operates solely based on the presence or absence of pressure without requiring an external power source. It works by using a diaphragm or piston mechanism to detect pressure changes in a system and trigger an electrical contact accordingly.

- Pressure Detection – The switch contains a diaphragm, piston, or bourdon tube that responds to changes in system pressure. The pressure from the process fluid pushes against this sensing element.

- Spring Mechanism – Inside the switch, a calibrated spring is used to set the activation threshold. The force exerted by the diaphragm or piston compresses this spring as pressure increases.

- Contact Switching – When the pressure reaches or exceeds the pre-set threshold:

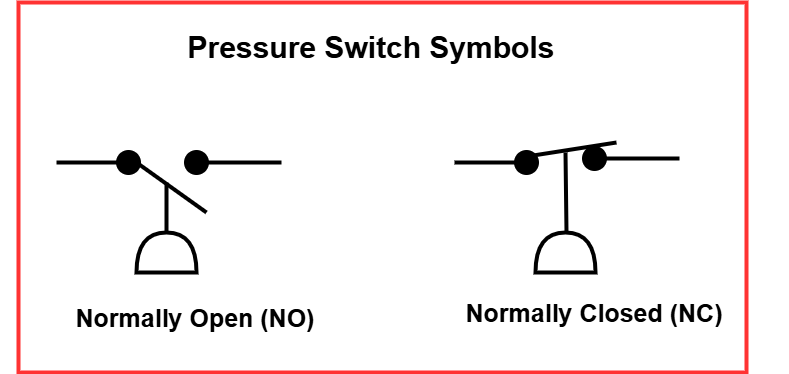

- In a Normally Open (NO) switch, the contacts close, allowing electrical current to pass through and activate connected equipment.

- In a Normally Closed (NC) switch, the contacts open, interrupting the electrical circuit and turning off the connected device.

- Resetting the Switch – If the pressure drops below the cut-out point, the diaphragm or piston returns to its original position, resetting the switch and either closing or opening the circuit, depending on its configuration.

Common Applications of Pressure Switches

Pressure switches are widely used in domestic, commercial, and industrial applications to monitor and control pressure levels in various systems. Some common uses include:

- Air Compressor Pressure Switches – Used in HVAC systems, gas cylinders, and air pumps to regulate air pressure. They ensure compressors turn on and off as needed to maintain optimal system pressure.

- Oil Pressure Switches – Found in automobile and industrial engines, these switches monitor engine oil pressure. If the oil pressure drops below a preset level, they trigger an alarm or shut down the engine to prevent damage.

- Furnace Pressure Switches – Used in residential and industrial furnaces as safety devices. If air pressure is too low during startup, they shut down the furnace to prevent hazards.

- Well Pump Pressure Switches – Essential for residential and commercial water systems, these switches control water pumps to ensure a steady water supply while preventing excessive pressure buildup.

- Water Pump Pressure Switches – Used in homes, farms, and industries to automatically regulate water flow and pressure in pumping systems.

- Vacuum Pressure Switches – Designed to measure negative pressure (vacuum) in boilers, electric heaters, and air compressors, ensuring safe and efficient operation.

Pressure Switch Selection Criteria

Choosing the right pressure switch requires careful evaluation of several factors to ensure reliability and efficiency in a given application. Below are key selection criteria:

- Operating Temperature – The switch’s components must withstand the operating temperature of the system. Certain materials degrade at high temperatures, affecting performance and durability.

- Process Fluid Compatibility – The chemical properties of the process fluid determine the choice of materials for wetted parts, such as ports, seals, and sensing elements. These components must resist degradation mechanisms like corrosion, oxidation, or erosion to ensure long-term reliability.

- Type of Pressure – Pressure switches are designed for positive, negative (vacuum), or compound pressures. Diaphragm-based switches work best for vacuum and low-pressure applications, while piston-type switches are more suitable for high-pressure systems.

- Pressure Range – Each pressure switch has a defined operating range with cut-in and cut-out pressures. For optimal performance and safety, it is recommended to set the switch point at 40–60% of its maximum pressure range.

- Environmental Factors – Additional considerations such as humidity, vibration, and exposure to chemicals should be evaluated to select a durable and reliable pressure switch for the intended application.

Pressure Switch vs. Pressure Transducer

It’s important to distinguish a pressure switch from a pressure transducer. While both deal with pressure sensing, a pressure transducer converts pressure into an electrical output signal for monitoring or data acquisition, whereas a pressure switch simply activates or deactivates a system component based on a pressure threshold.

Useful Resources- Pressure switch Wikipedia

Read Next: