In industrial process plants, accurate level measurement is essential for safe and efficient operation. One device that plays a critical role in this task is the bridle. But what is a bridle, and why is it widely used in refineries, chemical plants, food processing units, power plants, and storage facilities?

This detailed guide explains everything you need to know about bridle piping, pipe bridles, level bridles, and level gauge bridles, including construction, working, benefits, applications, and types of instruments used.

What is a Bridle?

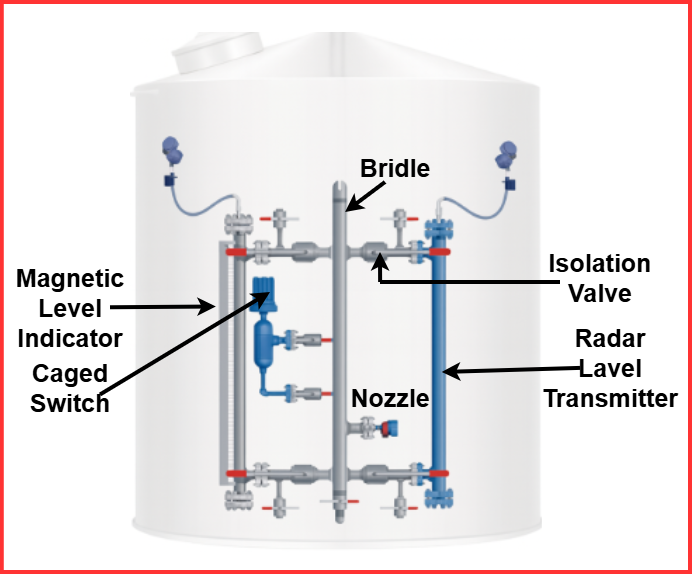

A bridle—also known as a cage, bypass pipe, isolating column, external chamber, or piping bridle—is a vertical external pipe mounted on the side of a storage tank or process vessel. It is typically connected using side–side or side–bottom nozzles.

Because the liquid inside the bridle pipe rises and falls at the same level as the liquid inside the vessel, it becomes an ideal external chamber for installing level measurement instruments.

Simple Definition

A bridle is an external bypass chamber attached to a process vessel that allows engineers to mount level instruments safely without inserting equipment directly into the vessel.

Why is it Used?

It provides a stable, isolated, safe, and obstruction-free place to install level gauges, transmitters, switches, and controllers.

How Does a Bridle Work?

A piping bridle works on the principle of communicating vessels. When two chambers are connected, the fluid level naturally equalizes.

As the liquid level inside the tank increases or decreases, the level inside the bridle also changes accordingly. This equalization allows precise level measurement—even in harsh, pressurized, or turbulent conditions.

Why Use a Bridle for Level Measurement?

The use of a level bridle gives multiple advantages to designers, operators, and maintenance teams.

1. Isolation from the Main Process

Instruments installed on the bridle are isolated using block valves. This allows:

- Safe maintenance

- Easy calibration

- Zero disturbance to the ongoing process

2. Fewer Connections on the Vessel

A bridle minimizes the number of instrument nozzles directly on the tank. This is especially valuable for:

- Boiler code vessels

- ASME pressure vessels requiring certified welders

3. Smart, Prudent Design

Level instrumentation is often the last consideration during design. A bridle helps avoid:

- Late design changes

- Additional vessel penetrations

- Complex retrofitting

4. Saves Time During Installation

Ordering a factory-built bridle with mounted level instruments reduces project delays at commissioning time.

5. Avoids Internal Obstruction Issues

A pipe bridle keeps instruments away from:

- Mixers

- Agitators

- Internals

- Aerators

- Baffles

- Heating coils

6. Reduces Turbulence & Foam

In a turbulent or foamy process tank, the bridle provides a calm environment for accurate level measurement.

7. Supports Multiple Instruments

One bridle can carry several level instruments on a single chamber.

Common Instruments Installed on a Bridle

Several level measurement technologies are compatible with bridle piping systems.

1. Guided Wave Radar (GWR)

- Ideal for high temperature & high-pressure applications

- Works reliably with changing densities

- Fast configuration and high accuracy

2. Magnetic Level Indicators (MLI)

- Used in harsh industrial applications

- Provide local visual indication using magnetic flags

- Can be paired with transmitters for remote readings

3. Magnetostrictive Transmitters

- High accuracy & excellent linearity

- Typically mounted externally on magnetic level indicators

4. External Cage Float Switches

- Suitable for high/low level switching

- Available in ASME B31.1 and B31.3 designs

5. Displacer Controllers

- Operate on buoyancy principles

- Effective in challenging conditions such as:

- Foam

- Turbulence

- Vapors

- Varying dielectric

6. Ultrasonic Point Level Sensors

- Mounted horizontally on the bridle

- Used for high/low level alarms

7. Thermal Dispersion Level Switches

- Offer high performance for interface detection

- Ideal for nozzle-mounted installations

Types of Bridles Used in Industry

1. Standard Level Bridle

For general liquid level measurement with radar, float, or displacer.

2. Magnetic Level Gauge Bridle

Combination of MLI with a bypass chamber for high accuracy and local display.

3. Boiler Drum Bridle

Specialized ASME-coded bridle for steam drum level applications.

4. Interface Detection Bridle

Used for measuring the boundary between two immiscible liquids (oil–water, condensate–hydrocarbon, etc.).

Applications of Bridle Piping

Bridles are commonly used in:

- Chemical reactors

- Oil storage tanks

- Boiler drums

- High-pressure steam systems

- Distillation columns

- Separator vessels

- Process tanks with internal obstructions

- Hydrocarbon storage systems

- Food & beverage tanks

Any process vessel requiring accurate, stable, and accessible level measurement benefits from a pipe bridle.

Advantages of Using a Bridle for Level Gauging

| Feature | Benefit to the Plant |

| Isolation | Safe calibration & maintenance |

| Fewer connections | Reduced welding and fabrication costs |

| Reduced turbulence | Higher accuracy |

| Supports multiple instruments | Flexibility in measurement |

| Saves installation time | Faster commissioning |

| Avoids vessel obstructions | Safe and reliable measurement |

| Compatible with many technologies | Universal application |

Conclusion

A bridle or bridle pipe is an essential component in modern process industries. It provides a safe, isolated, and accurate way to measure liquid levels in tanks and pressure vessels. Whether you are using guided wave radar, magnetic level gauges, float switches, or ultrasonic sensors, a well-designed bridle piping system ensures dependable performance.

Read Next: