A reflex gauge is essential for reading the liquid level in tanks, boilers, and vessels. These gauges provide a clear, accurate, and reliable means of monitoring fluid levels in various applications. This article explores reflex level gauges, their construction, main components, and advantages.

What is a Reflex Level Gauge?

A reflex level gauge is a device used to measure the liquid level within a tank or vessel. It operates on the principle of light refraction and reflection through a specially designed sight glass. Light is absorbed When it hits the liquid, making it appear dark. In contrast, light reflects off the vapor space, which appears bright. This creates a distinct and visible contrast between the liquid and vapor interface, allowing for easy level determination.

Construction of a Reflex Level Gauge

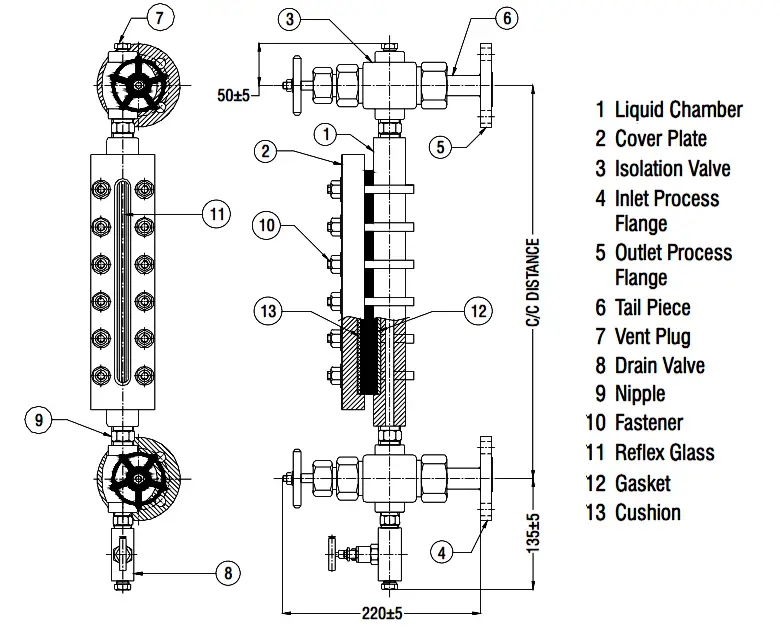

The construction of a reflex level gauge is robust and designed to withstand high pressures and temperatures. Here’s a breakdown of its construction:

- Body: Typically made of metal such as carbon steel or stainless steel, the body houses the glass and contains the fluid. It is designed to be strong enough to handle the tank or vessel’s operating conditions.

- Sight Glass: The sight glass is the most critical component. It is made from specially designed reflex glass, which has grooved surfaces on one side. These grooves increase the visibility of the liquid level by enhancing the refraction and reflection of light.

- Gaskets and Seals: These are used to prevent leaks and maintain the gauge’s integrity under varying pressure and temperature conditions.

- Valves: Isolation valves are often included at the top and bottom of the gauge for safety and maintenance. They allow the gauge to be isolated from the tank without emptying it.

Main Components

- Chamber: The main body or chamber holds the liquid and connects to the vessel or tank.

- Reflex Glass: This specially designed glass allows for visibility of the liquid level.

- Cover Plate: This component protects the glass and is usually bolted to the chamber.

- Gaskets: These ensure a tight seal between the glass and the chamber.

- Valves: Used to isolate the gauge for maintenance or in case of glass breakage.

Advantages of Reflex Level Gauges

Reflex level gauges offer several advantages that make them popular in industrial applications:

- Visibility: The design of the reflex glass makes the liquid level highly visible, even from a distance.

- Durability: Made from robust materials, these gauges can handle harsh conditions and high temperatures.

- Low Maintenance: The simplicity of the design ensures that reflex level gauges require minimal maintenance.

- Safety: The gauge’s use of strong, durable materials and the inclusion of isolation valves enhance its safety.

- Accuracy: They provide a reliable and accurate measure of liquid level, which is crucial for many industrial processes.

Conclusion

Reflex level gauges are invaluable tools in industries where precise liquid level measurement is critical. Their robust construction and the clarity they offer in reading liquid levels make them a preferred choice in many settings. With proper installation and maintenance, these gauges can offer years of reliable service, contributing significantly to the safety and efficiency of industrial operations.